|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

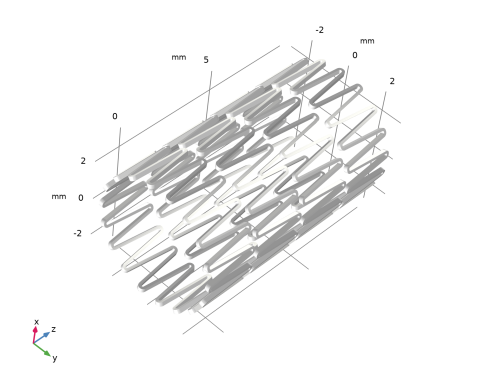

Browse to the model’s Application Libraries folder and double-click the file sma_stent_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Intervals subsection. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Material Models>Shape Memory Alloy.

|

|

2

|

|

3

|

|

4

|

Locate the Model Input section. From the T list, choose User defined. In the associated text field, type temperature(para).

|

|

5

|

Locate the Shape Memory Alloy section. Find the Austenite subsection. From the list, choose Austenite (mat2).

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, expand the Shape Memory Alloy 1 node, then click Phase Transformation Direction 1.

|

|

2

|

In the Settings window for Phase Transformation Direction, locate the Phase Transformation Direction section.

|

|

3

|

|

4

|

In the text field, type pw1(para).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Find the Expression for remaining selection subsection. In the Volume reference temperature text field, type -27[degC].

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid)>Shape Memory Alloy 1 click Thermal Expansion 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Equation-Based Contributions.

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

4

|

|

5

|

In the Dependent variable quantity table, enter the following settings:

|

|

6

|

|

7

|

In the Source term quantity table, enter the following settings:

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

8

|

Click

|

|

9

|

|

10

|

|

11

|

|

12

|

Click Replace.

|

|

13

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Parameter values list, select the solution steps from 1 to 2.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

8

|

|

9

|

|

10

|

Click

|

|

11

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Volume, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Shape memory alloy>solid.xi_M - Martensite volume fraction.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

10

|

|

11

|

|

12

|

|

13

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose union1.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry, Ctrl-click to select Circle 1 (c1), Circle 2 (c2), Tangent 1 (tan1), and Union 1 (uni1).

|

|

2

|

Right-click and choose Duplicate.

|

|

1

|

|

2

|

|

3

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose union2.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose union2.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

On the object uni1, select Point 4 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

On the object uni1, select Point 7 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Rectangle 1 (r1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Resulting Selection section. Find the Cumulative selection subsection. From the Contribute to list, choose Delete.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Disk Selection 1 (disksel1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

6

|

Click

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Resulting Selection section. Find the Cumulative selection subsection. From the Contribute to list, choose Delete.

|

|

8

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Box Selection 3 (boxsel3) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

Select the object ext1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Click the Angles button.

|

|

4

|

|

5

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

1

|

|

2

|

|

3

|

|

4

|