|

|

•

|

Inlet (z = 0)

|

|

•

|

|

•

|

|

•

|

Inlet (z = 0)

|

|

•

|

|

•

|

|

•

|

Inlet (z = 0)

|

|

•

|

|

•

|

Frequency factor, A = 16.96E12 1/h

|

|

•

|

|

•

|

Thermal conductivity of the reaction mixture, ke = 0.559 W/(m·K)

|

|

•

|

|

•

|

Inlet temperature, T0 = 312 K

|

|

•

|

Inlet temperature of the coolant, Ta0 = 277 K

|

|

•

|

|

•

|

|

•

|

Mass flow rate of coolant, mc = 0.1 kg/s

|

|

•

|

|

•

|

|

•

|

|

•

|

Heat capacity at inlet, Cp0 = (146.54*cA0_po+75.36*cB0+81.095*cMe0)/rho0 J/(kg·K) (here, the numerical factors are the molar specific heat values in the unit J/(mol·K))

|

|

•

|

Heat capacity per mass of coolant, Cpc = 4180 J/(kg·K)

|

|

•

|

|

•

|

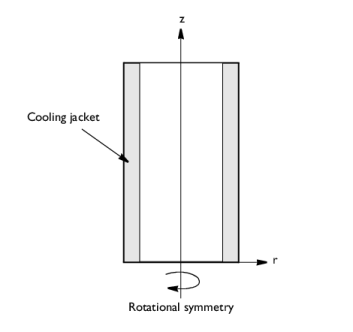

Reactor radius, Ra = 0.1 m

|

|

•

|

Reactor length, L = 1 m

|

|

•

|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

|

6

|

Click Add.

|

|

7

|

In the Select Physics tree, select Mathematics>PDE Interfaces>Lower Dimensions>Coefficient Form Boundary PDE (cb).

|

|

8

|

Click Add.

|

|

9

|

In the Dependent variables table, enter the following settings:

|

|

10

|

|

11

|

|

12

|

Click

|

|

13

|

|

14

|

Click OK.

|

|

15

|

|

16

|

click

|

|

17

|

|

18

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file tubular_reactor_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file tubular_reactor_variables.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

Specify the u vector as

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

Specify the u vector as

|

|

4

|

Locate the Heat Conduction, Fluid section. From the k list, choose User defined. In the associated text field, type ke.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Coefficient Form Boundary PDE (cb) click Coefficient Form PDE 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

In the Settings window for Dirichlet Boundary Condition, locate the Dirichlet Boundary Condition section.

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

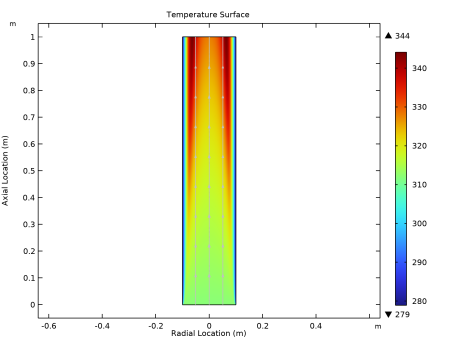

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Variables>xA - Conversion species A.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

3

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>xA - Conversion species A.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|