|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file differential_pumping_geom_sequence.mph.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file differential_pumping_parameters.txt.

|

|

5

|

Click the

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file differential_pumping_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Free Molecular Flow (fmf) click Molecular Flow 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

In the Model Builder window, expand the Results>Datasets node, then click Study 1/Solution 1 (sol1).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Incident Molecular Flux (fmf) node, then click Surface.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Circle.

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Diamond.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

Clear the Pressure check box.

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Free Molecular Flow 2 (fmf2) click Molecular Flow 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Incident Molecular Flux (fmf2) node, then click Surface.

|

|

2

|

|

1

|

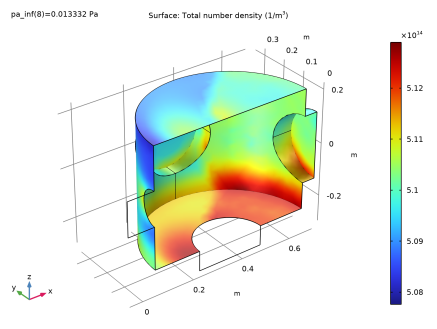

In the Model Builder window, expand the Results>Total Number Density (fmf2) node, then click Surface.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

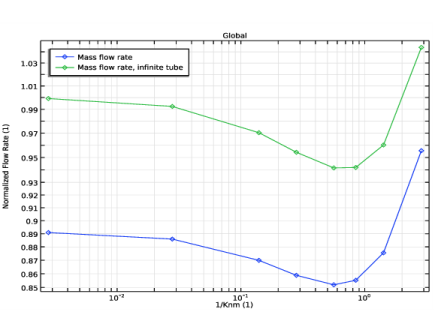

Select the y-axis label check box. In the associated text field, type number density (1/m<sup>3</sup>).

|

|

7

|

|

8

|

|

9

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Axis section. From the Axis type list, choose y-axis. By changing the axis, the cylinder is oriented accordingly.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Clear the Keep interior boundaries check box. This combines the selected cylinders into an object with a single domain.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object uni2 only.

|

|

3

|

|

4

|

|

5

|

Select the object cyl7 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object par1(1), select Domain 1 only.

|

|

6

|

On the object par1(2), select Domain 1 only.

|

|

7

|

On the object par1(3), select Domain 1 only.

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

On the object fin, select Domain 3 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object fin, select Boundary 19 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

Click

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 9 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object fin, select Boundaries 11 and 12 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 25 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 35 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

Click

|

|

9

|

In the Add dialog box, in the Selections to subtract list, choose Cylinder Selection 1 and Cylinder Selection 2.

|

|

10

|

Click OK.

|