|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Electromagnetics-Structure Interaction>Piezoelectricity>Piezoelectricity, Solid.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Definitions>View 1 node, then click Axis.

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

Locate the Parameters section. In the table, enter the following settings:

|

|

1

|

|

2

|

In the Settings window for Parameters, type Parameters 2 - Material properties in the Label text field.

|

|

3

|

Locate the Parameters section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. From the Show in physics list, choose All levels.

|

|

8

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

8

|

|

9

|

|

10

|

|

11

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

12

|

|

13

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Low impedance - SiO2 (r4) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

6

|

|

7

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Array - SiO2 (arr1) and choose Duplicate.

|

|

2

|

|

3

|

Locate the Input section. Find the Input objects subsection. Click to select the

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Low impedance - SiO2 (r4) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Left fixed B.C., Right fixed B.C., and Bottom fixed B.C..

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Piezoelectric Material 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Built-in>Molybdenum.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Control Entities section. Clear the Smooth across removed control entities check box.

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

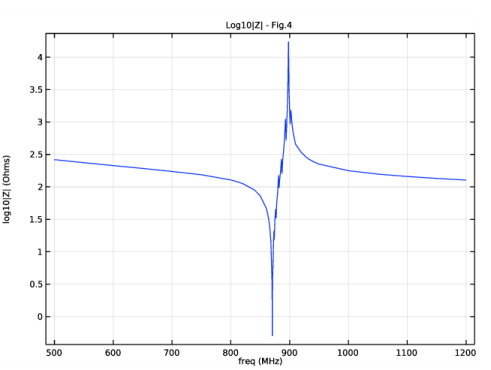

In the Frequencies text field, type range(500,50,800) range(810,10,850) range(860,2,870) range(870.1,0.05,870.9) range(871,1,910) 920 930 940 range(950,50,1200).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Frequency Response/Solution 2 (sol2).

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Frequency Response/Solution 2 (sol2).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

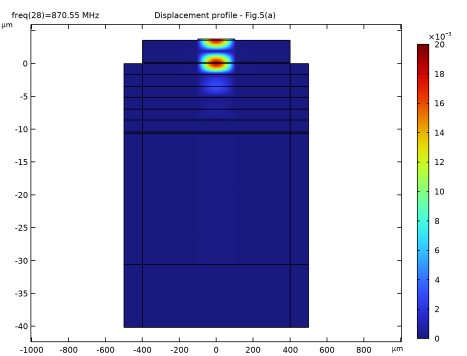

In the Settings window for 2D Plot Group, type Displacement profile - Fig.5(a) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Frequency Response/Solution 2 (sol2).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

4

|

Locate the y-Coordinates section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|