|

|

1

|

|

2

|

In the Select Physics tree, select AC/DC>Electromagnetics and Mechanics>Piezoelectricity>Piezoelectricity and Pyroelectricity.

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

1000 Ω

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Units section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Electrostatics (es) click Charge Conservation, Piezoelectric 1.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Piezoelectric Material 1.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Settings window for Time Dependent, type Time Dependent - Pyroelectricity Only in the Label text field.

|

|

2

|

|

3

|

|

5

|

|

6

|

Click

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

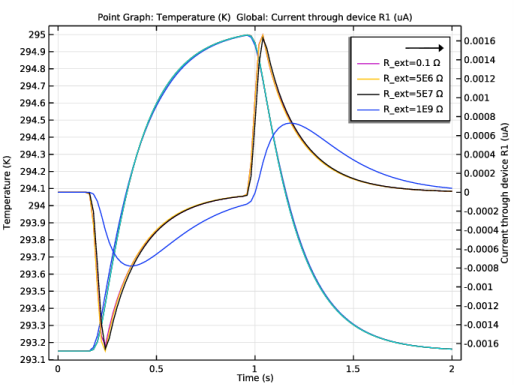

In the Settings window for 1D Plot Group, type Temperature and Current Density, Full Model in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Select the Description check box.

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, right-click Temperature and Current Density, Full Model and choose Global.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

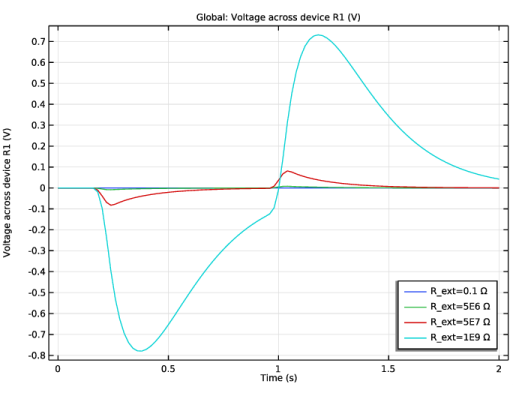

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Electrical Circuit>Devices>R1>cir.R1_v - Voltage across device R1 - V.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

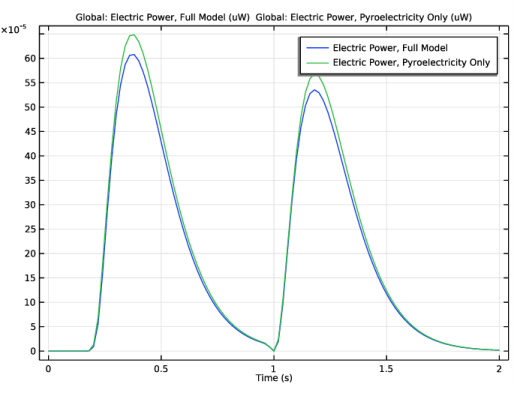

In the Settings window for 1D Plot Group, type Full Model vs. Pyroelectricity Only in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Global, type Electric Power, Pyroelectricity Only in the Label text field.

|

|

3

|

|

4

|

|

5

|