|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Electromagnetics-Structure Interaction>Piezoelectricity>Piezoelectricity, Solid.

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

12000 Ω

|

|||

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

6

|

|

1

|

|

2

|

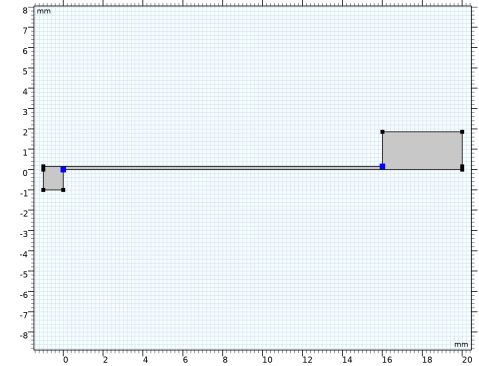

On the object uni1, select Points 7 and 8 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Piezoelectric Material 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Frequency Response>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Frequency Response>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 click Direct.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Frequency Response: Voltage & Power in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Load Dependence>Solver Configurations>Solution 2 (sol2)>Stationary Solver 1 node, then click Direct.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

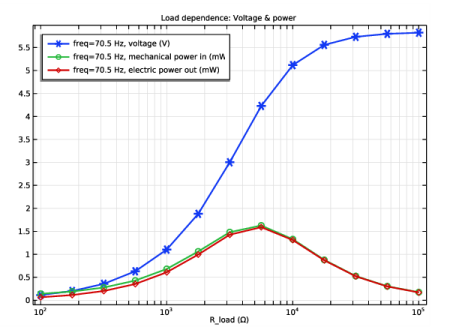

In the Settings window for 1D Plot Group, type Load Dependence: Voltage & Power in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Acceleration Dependence>Solver Configurations>Solution 3 (sol3)>Stationary Solver 1 node, then click Direct.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

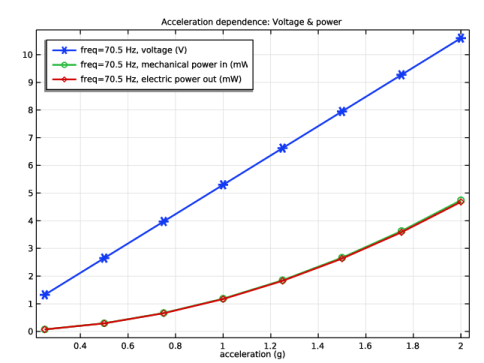

In the Settings window for 1D Plot Group, type Acceleration Dependence: Voltage & Power in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|