|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Electromagnetics-Structure Interaction>Ferroelectroelasticity.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

0.0133 m4/C²

|

|||

|

-0.00606 m4/C²

|

|||

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

In the Settings window for Charge Conservation, Ferroelectric, locate the Ferroelectric Material Properties section.

|

|

4

|

Find the Anhysteretic polarization subsection. From the Anhysteretic polarization shape list, choose Hyperbolic tangent.

|

|

5

|

Find the Effective electric field subsection. From the α list, choose User defined. In the associated text field, type 0.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Electrostriction 1 (efe1).

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

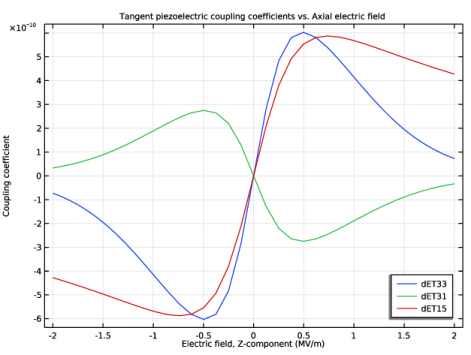

Locate the Title section. In the Title text area, type Tangent piezoelectric coupling coefficients vs. Axial electric field.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

In the Model Builder window, expand the Tangent Piezoelectric Coupling Coefficients node, then click Point Graph 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|