|

|

kg/m3

|

|||

|

2

|

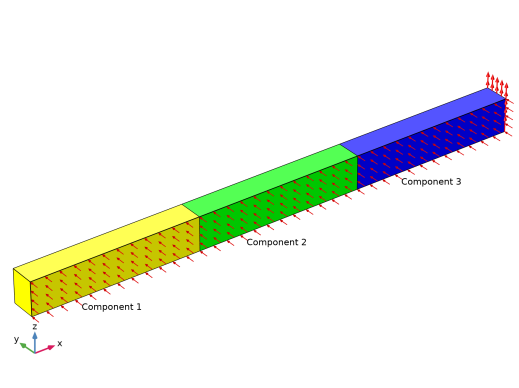

Components 1 and 3 are reduced using CMS, while component 2 is unreduced. This corresponds to a hybrid CMS and FEM solution to the problem.

|

|

1

|

The contribution of the load in the y direction is applied external to the ROM.

|

|

2

|

The contribution of the load in the z direction is internal to the ROM, and is parameterized by a control variable.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the object blk1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Reduced Flexible Components 1.

|

|

2

|

In the Settings window for Reduced Flexible Components, locate the Component Mode Synthesis section.

|

|

3

|

|

4

|

Click CMS Configuration in the upper-right corner of the Component Mode Synthesis section. From the menu, choose Configure CMS Study.

|

|

1

|

In the Model Builder window, expand the CMS Study>Step 3: Model Reduction node, then click Time Dependent.

|

|

2

|

|

3

|

|

4

|

Right-click and choose Enable.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Study, Full Model, Ctrl-click to select Step 1: Stationary and Step 2: Time Dependent.

|

|

2

|

Right-click and choose Copy.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Right-click and choose Disable.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions right-click Point Probe 1 (point1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

Click to expand the Table and Window Settings section. From the Output table list, choose New table.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

In the Model Builder window, under Results>Constrained Eigenmodes right-click Volume 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

In the Model Builder window, under Results>Constraint Modes right-click Volume 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the tree, select Global Definitions>Reduced-Order Modeling>Reduced Component 1 (rom1_n_rfc1_solid_1) and Global Definitions>Reduced-Order Modeling>Reduced Component 2 (rom1_n_rfc1_solid_2).

|

|

5

|

|

6

|

|

7

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

7

|

In the tree, select Global Definitions>Reduced-Order Modeling>Reduced Component 1 (rom1_n_rfc1_solid_1) and Global Definitions>Reduced-Order Modeling>Reduced Component 2 (rom1_n_rfc1_solid_2).

|

|

8

|

|

9

|

|

10

|

Right-click and choose Disable.

|