|

|

•

|

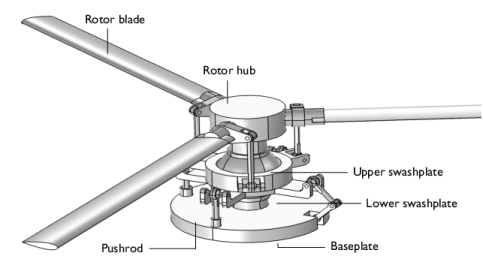

Pushrod (3 in number, stationary)

|

|

•

|

Baseplate-Swashplate Link (2 in number, stationary)

|

|

•

|

Rotor Blade (3 in number, rotating)

|

|

•

|

Swashplate-Blade Link (3 in number, rotating)

|

|

•

|

|

•

|

Cl — lift coefficient

|

|

•

|

Ur — relative velocity at a point over the rotor blades

|

|

•

|

α — angle of attack of rotor blades

|

|

•

|

ω — angular velocity of rotor blades

|

|

•

|

vf — forward speed of helicopter

|

|

•

|

d — distance of a point over the rotor blades from the center of rotation

|

|

•

|

x, y — spatial coordinates of a point over the rotor blades

|

|

•

|

A Joint node can establish a direct connection between Rigid Material nodes. However, for flexible elements, Attachment nodes are needed to define the connection boundaries.

|

|

•

|

Constraint boundary conditions like Rigid Connector and Prescribed Displacement cannot be used with a Rigid Material node. Hence, the Prescribed Displacement/Rotation node (subnode to Rigid Material) is used to constrain or prescribe the corresponding degrees of freedom.

|

|

•

|

The connections set up in the model can be reviewed in the Joints Summary section at the physics node.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file helicopter_swashplate.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Smoothing section.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Specify the ω vector as

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Prescribed Displacement at Center of Rotation section. Select the Prescribed in x direction check box.

|

|

5

|

|

6

|

|

7

|

|

8

|

Specify the Ω vector as

|

|

9

|

|

1

|

|

2

|

In the Settings window for Rigid Material, type Rigid Material: Upper Swashplate in the Label text field.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Axes of Joint section. From the Joint translational axis list, choose Attached on source.

|

|

7

|

|

8

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Prescribed Rotational Motion section. From the Activation condition list, choose Never active.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, under Study: Rigid Blades>Solver Configurations>Solution 1 (sol1) click Time-Dependent Solver 1.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

4

|

In the tree, select Component 1 (comp1)>Multibody Dynamics (mbd), Controls spatial frame>Rigid Material: Rotor Blade1, Component 1 (comp1)>Multibody Dynamics (mbd), Controls spatial frame>Rigid Material: Rotor Blade2, and Component 1 (comp1)>Multibody Dynamics (mbd), Controls spatial frame>Rigid Material: Rotor Blade3.

|

|

5

|

Right-click and choose Disable.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study: Flexible Blades>Solver Configurations>Solution 2 (sol2)>Time-Dependent Solver 1 node, then click Fully Coupled 1.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Study: Flexible Blades/Solution 2 (4) (sol2) node, then click Selection.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Displacement: Flexible Blade1 in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study: Flexible Blades/Solution 2 (3) (sol2).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study: Flexible Blades/Solution 2 (2) (sol2).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

Select the x-axis label check box. In the associated text field, type Angular rotation of rotor (deg).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>FL_tot1 - Total lift force - blade1 - N.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>FL_tot2 - Total lift force - blade2 - N.

|

|

4

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>FL_tot3 - Total lift force - blade3 - N.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

Select the x-axis label check box. In the associated text field, type Angular rotation of rotor (deg).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>FL_tot1 - Total lift force - blade1 - N.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>FL_tot1_alphaM - Total lift force (mean)- blade1 - N.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>w_tip - Tip displacement z direction - m.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Select the x-axis label check box. In the associated text field, type Angular rotation of rotor (deg).

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

4

|

In the tree, select Component 1 (comp1)>Multibody Dynamics (mbd)>Rigid Material: Rotor Blade1, Component 1 (comp1)>Multibody Dynamics (mbd)>Rigid Material: Rotor Blade2, Component 1 (comp1)>Multibody Dynamics (mbd)>Rigid Material: Rotor Blade3, Component 1 (comp1)>Multibody Dynamics (mbd)>Prismatic Joint 1>Prescribed Motion 1, Component 1 (comp1)>Multibody Dynamics (mbd)>Reduced Slot Joint 1>Prescribed Motion 1, and Component 1 (comp1)>Multibody Dynamics (mbd)>Prismatic Joint 2>Prescribed Motion 1.

|

|

5

|

Right-click and choose Disable.

|

|

6

|

|

7

|

In the Settings window for Study, type Study: Flexible Blades[Eigenfrequency] in the Label text field.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Mode Shape (mbd)>Surface node, then click Deformation.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|