|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

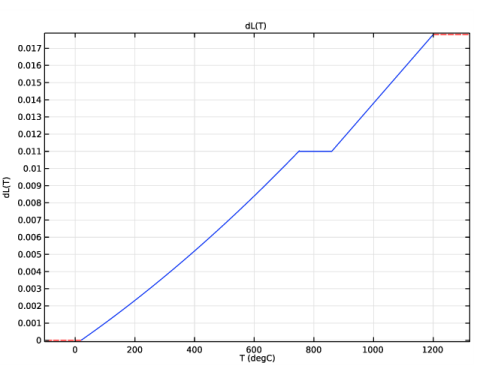

Locate the Material Properties section. In the Material properties tree, select Solid Mechanics>Thermal Expansion>Thermal strain (dL).

|

|

5

|

|

1

|

|

2

|

Right-click Component 1 (comp1)>Materials>Steel (mat1)>Thermal expansion (ThermalExpansion) and choose Functions>Piecewise.

|

|

3

|

|

4

|

|

5

|

Find the Intervals subsection. In the table, enter the following settings:

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials>Steel (mat1) click Thermal expansion (ThermalExpansion).

|

|

2

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Roller.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Model Input section. From the T list, choose User defined. In the associated text field, type T_in.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

3

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file fire_effects_thermal_elongation_dlref.txt.

|

|

6

|

Find the Functions subsection. In the table, enter the following settings:

|

|

7

|

|

8

|

|

1

|

|

2

|

|

4

|

|

1

|

Go to the Table window.

|