|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object r4 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object uni1, select Points 6 and 7 only.

|

|

6

|

On the object uni2, select Points 4 and 5 only.

|

|

7

|

|

8

|

On the object uni1, select Points 6 and 7 only.

|

|

9

|

On the object uni2, select Points 4 and 5 only.

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file pem_gdl_species_transport_2d_parameters.txt.

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

In the tree, select Fuel Cell and Electrolyzer>Polymer Electrolytes>Nafion, EW 1100, Vapor Equilibrated, Protonated.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials click Nafion, EW 1100, Vapor Equilibrated, Protonated (mat1).

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Fuel Cell and Electrolyzer>Polymer Electrolytes>Nafion, EW 1100, Vapor Equilibrated, Protonated.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Find the Transport mechanisms subsection. Select the Use Darcy’s Law for momentum transport check box.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc) click H2 Gas Diffusion Layer 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Thin H2 Gas Diffusion Electrode Reaction, locate the Equilibrium Potential section.

|

|

3

|

From the Eeq list, choose User defined. Due to the user-defined kinetics expression, the equilibrium potential parameter is not in use in this model. Therefore keep the default value of 0 V.

|

|

4

|

Locate the Electrode Kinetics section. From the iloc,expr list, choose User defined. In the associated text field, type i_a.

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc) click Thin O2 Gas Diffusion Electrode 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Thin O2 Gas Diffusion Electrode Reaction, locate the Equilibrium Potential section.

|

|

3

|

From the Eeq list, choose User defined. Also for the oxygen reduction reaction, the equilibrium potential parameter is not in use in this model. Therefore keep the default value of 0 V.

|

|

4

|

Locate the Electrode Kinetics section. From the iloc,expr list, choose User defined. In the associated text field, type i_c.

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc) click Electronic Conducting Phase 1.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

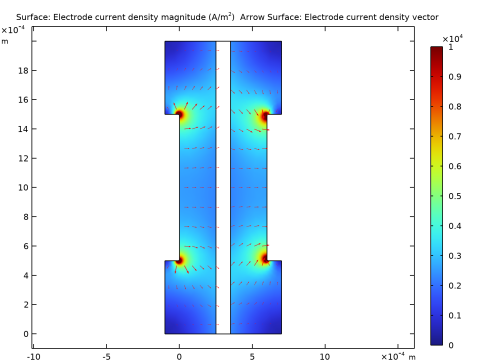

In the Settings window for 2D Plot Group, type GDL Current Density Distribution in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.IsMag - Electrode current density magnitude - A/m².

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.Isx,fc.Isy - Electrode current density vector.

|

|

3

|

|

4

|

|

1

|

|

2

|

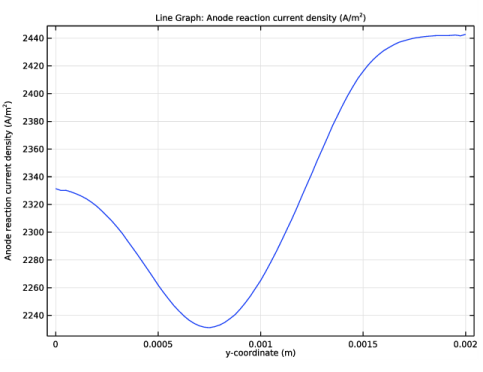

In the Settings window for 1D Plot Group, type Anode Reaction Current Density in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>i_a - Anode current density - A/m².

|

|

5

|

|

6

|

Select the Description check box. In the associated text field, type Anode reaction current density.

|

|

7

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Geometry>Coordinate>y - y-coordinate.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

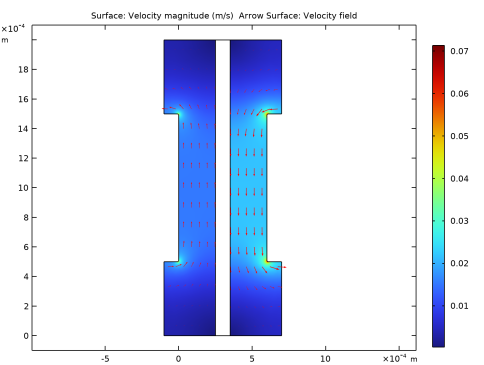

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.U - Velocity magnitude - m/s.

|

|

1

|

|

2

|

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.u,fc.v - Velocity field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.u,fc.v - Velocity field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|