|

|

Δτ/2+0.20σn (MPa)

|

Δτ/2+0.27σn (MPa)

|

Δσn(MPa)

|

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

3

|

|

1

|

|

2

|

On the object csol1, select Point 5 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the object fil1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Work Plane 1 (wp1) and choose Revolve.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Fixed Constraint.

|

|

1

|

|

1

|

|

2

|

|

3

|

Specify the F vector as

|

|

4

|

|

1

|

|

2

|

|

3

|

Specify the M vector as

|

|

4

|

|

1

|

In the Model Builder window, under Global Definitions>Load and Constraint Groups click Load Group 1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Global Definitions>Load and Constraint Groups click Load Group 2.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Add four times.

|

|

6

|

|

1

|

|

2

|

|

1

|

|

3

|

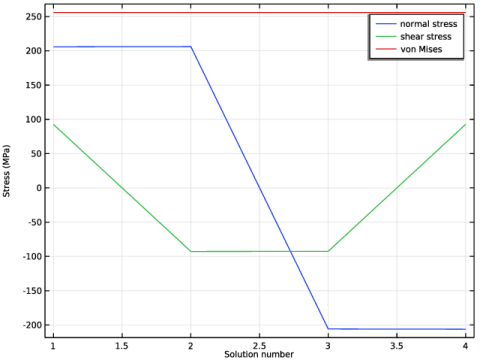

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress (Gauss points)>Second Piola-Kirchhoff stress, Gauss point evaluation (material and geometry frames) - N/m²>solid.SGpYY - Second Piola-Kirchhoff stress, Gauss point evaluation, YY-component.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

4

|

|

5

|

|

1

|

|

2

|

Right-click Component 1 (comp1)>Fatigue Normal Stress and choose the boundary evaluation Stress-Based.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Solid Mechanics (solid).

|

|

4

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Fatigue.

|

|

5

|

|

6

|

|

1

|

|

2

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

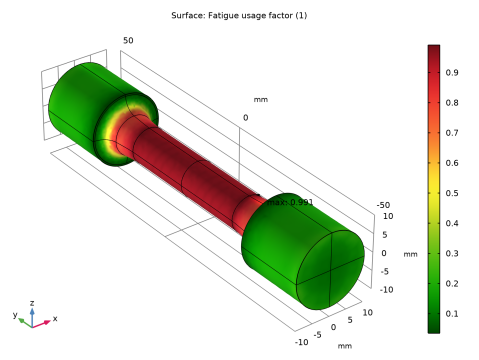

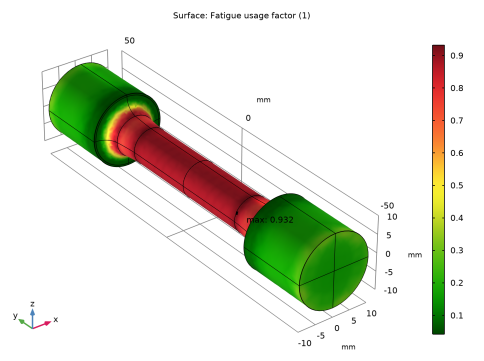

In the Settings window for 3D Plot Group, type Fatigue Usage Factor (Matake) in the Label text field.

|

|

1

|

|

2

|

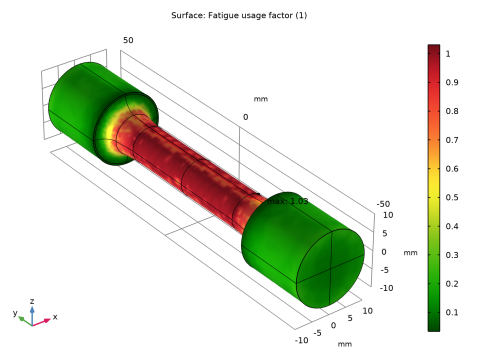

In the Settings window for 3D Plot Group, type Fatigue Usage Factor (Normal Stress) in the Label text field.

|