|

|

•

|

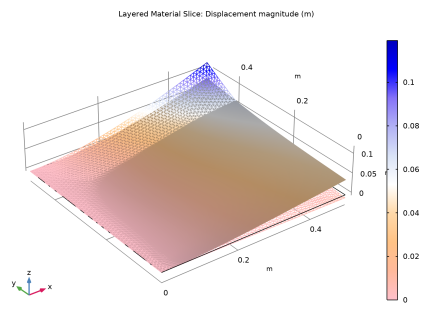

A total load of 1 kN is applied to one of the corners of the right end of the laminate in the form of a line load as shown in Figure 2.

|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file stacking_sequence_optimization_parameters.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Layered Shell (lshell) click Linear Elastic Material 1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

2

|

|

4

|

Click

|

|

6

|

Click

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Layers>Layered Material Link.

|

|

2

|

|

3

|

|

4

|

Click to expand the Preview Plot Settings section. In the Thickness-to-width ratio text field, type 0.4.

|

|

5

|

Click Section_bar in the upper-right corner of the Layered Material Settings section. From the menu, choose Layer Cross-Section Preview.

|

|

6

|

Click Section_bar in the upper-right corner of the Layered Material Settings section. From the menu, choose Layer Stack Preview.

|

|

1

|

In the Model Builder window, under Global Definitions>Materials click Material: Carbon-Epoxy (mat1).

|

|

2

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Stress, Slice (Original) node, then click Layered Material Slice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the tree, select Study 1: Original Layup/Solution 1 (sol1)>Layered Shell>Geometry and Layup (lshell)>Ply Angle (lshell).

|

|

3

|

|

4

|

In the tree, select Study 1: Original Layup/Solution 1 (sol1)>Layered Shell>Geometry and Layup (lshell)>First Principal Material Direction (lshell).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type First Principal Material Direction (Original) in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the tree, select Study 1: Original Layup/Solution 1 (sol1)>Layered Shell>Applied Loads (lshell)>Line Loads (lshell).

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

Click

|

|

9

|

Click

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the tree, select Study 2: Layup Optimization/Parametric Solutions 1 (sol3)>Layered Shell>Stress, Slice (lshell).

|

|

3

|

|

1

|

In the Model Builder window, expand the Stress, Slice (Optimized) node, then click Layered Material Slice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the tree, select Study 2: Layup Optimization/Parametric Solutions 1 (sol3)>Layered Shell>Geometry and Layup (lshell)>Ply Angle (lshell).

|

|

3

|

|

4

|

In the tree, select Study 2: Layup Optimization/Parametric Solutions 1 (sol3)>Layered Shell>Geometry and Layup (lshell)>First Principal Material Direction (lshell).

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type First Principal Material Direction (Optimized) in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Stress, Slice (Original) 1 node, then click Layered Material Slice 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Through-Thickness Location section. From the Location definition list, choose Reference surface.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

Click OK.

|

|

11

|

|

12

|

Select the Wireframe check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Results>Stress, Slice (Original) 1>Layered Material Slice 1 node, then click Deformation.

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Displacement: Original and Optimized in the Label text field.

|

|

3

|

|

4

|

|

5

|