|

|

•

|

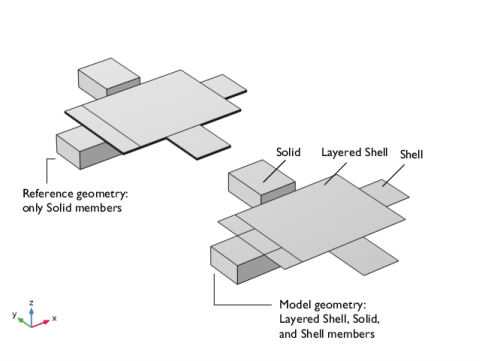

Boundaries of the Solid Mechanics interface shared with the Layered Shell interface, the connection is set up using Layered Shell-Structure Cladding multiphysics coupling.

|

|

•

|

Boundaries of the Solid Mechanics interface side-by-side with the Layered Shell interface, the connection is set up using the Layered Shell-Structure Transition multiphysics coupling.

|

|

•

|

Boundaries of the Shell interface parallel with the Layered Shell interface, the connection is set up using Layered Shell-Structure Cladding multiphysics coupling.

|

|

•

|

Edges of the Shell interface side-by-side with the Layered Shell interface, the connection is set up using the Layered Shell-Structure Transition multiphysics coupling.

|

|

{G12}

|

|

|

•

|

Boundary load of 10 kN is applied at the top surface of the middle plate modeled using layered shell.

|

|

•

|

Modeling a composite laminate requires a surface geometry (2D), in general called a base surface, and a Layered Material node, which adds an extra dimension (1D) to the base surface geometry in the surface normal direction. You can use the Layered Material functionality to model several layers stacked on top of each other having different thicknesses, material properties, and fiber orientations. Optionally, you can also specify the interface materials between the layers and control mesh elements in each layer.

|

|

•

|

From a constitutive model point of view, you can either use the Layerwise (LW) theory based Layered Shell interface or the Equivalent Single Layer (ESL) theory based Layered Linear Elastic Material node in the Shell interface.

|

|

•

|

The Layered Shell - Structure Cladding multiphysics coupling is used to model cladding between a Layered Shell interface and a Solid Mechanics, Shell or Membrane interface. In the Connection Settings section, shared and parallel boundaries options are provided to connect boundaries of different structural physics interfaces.

|

|

•

|

The Layered Shell - Structure Transition multiphysics coupling is used to couple side-by-side structural connection between a Layered Shell interface and a Solid Mechanics or Shell interface. This is a layered multiphysics coupling and in the Shell Properties section, it is possible to select only few layers for the connection.

|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Solid Mechanics (solid), Structural Mechanics>Shell (shell), and Structural Mechanics>Layered Shell (lshell).

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object spl1(1), select Boundary 1 only.

|

|

5

|

On the object spl1(3), select Boundary 1 only.

|

|

6

|

Locate the Distances section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

1

|

|

2

|

Select the object ext1(2) only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object spl1(4) only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Select the object wp2 only.

|

|

4

|

|

5

|

|

6

|

On the object mov3(4), select Boundary 1 only.

|

|

7

|

On the object mov3(5), select Boundaries 1 and 2 only.

|

|

8

|

Locate the Distances section. In the table, enter the following settings:

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object mov3(3), select Boundary 1 only.

|

|

5

|

Locate the Distances section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

2

|

|

4

|

Click

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Layers>Layered Material Link.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Linear Elastic Material 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Linear Elastic Material 2.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Layered Linear Elastic Material, locate the Linear Elastic Material section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Layered Shell-Structure Cladding, locate the Connection Settings section.

|

|

3

|

|

1

|

In the Physics toolbar, click

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

10

|

In the Settings window for Layered Shell-Structure Transition, locate the Connection Settings section.

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

Click OK.

|

|

1

|

In the Physics toolbar, click

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Boundary Selection, Layered Shell section. Click to select the

|

|

7

|

Locate the Boundary Selection, Structure section. Click to select the

|

|

9

|

|

10

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Layered Shell-Structure Transition, locate the Coupled Interfaces section.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Layered Material, type Layered Material: Top Layer in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Stress: Layered Shell, Bottom Layer in the Label text field.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Stress: Layered Shell, Top Layer in the Label text field.

|

|

1

|

In the Model Builder window, expand the Stress: Layered Shell, Top Layer node, then click Surface 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

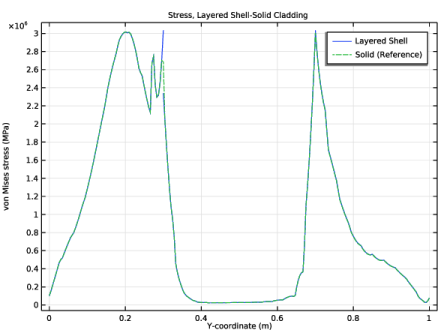

|

In the Settings window for 1D Plot Group, type Stress, Layered Shell-Solid Cladding in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

10

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Stress, Layered Shell-Shell Cladding in the Label text field.

|

|

1

|

In the Model Builder window, expand the Stress, Layered Shell-Shell Cladding node, then click Line Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Stress, Layered Shell-Shell Transition in the Label text field.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Stress, Layered Shell-Shell Transition node, then click Line Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Stress, Layered Shell-Solid Transition in the Label text field.

|

|

1

|

In the Model Builder window, expand the Stress, Layered Shell-Solid Transition node, then click Line Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|