|

|

4·104 (J/mol)

|

-1.1·105 (J/mol)

|

||

|

6·104 (J/mol)

|

-1·106 (J/mol)

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

|

7

|

Click Add.

|

|

8

|

|

9

|

Click Add.

|

|

10

|

|

11

|

In the Concentrations table, enter the following settings:

|

|

12

|

Click

|

|

13

|

|

14

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file plate_reactor_parameters.txt.

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file plate_reactor_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Reaction Thermodynamic Properties section. From the Enthalpy of reaction list, choose User defined.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Reaction Thermodynamic Properties section. From the Enthalpy of reaction list, choose User defined.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Fluids (ht) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1 right-click Free Triangular 1 and choose Duplicate.

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check boxes for Chemistry (chem), Heat Transfer in Fluids (ht), and Transport of Diluted Species (tds).

|

|

1

|

|

2

|

In the Settings window for Stationary, type Stationary - Transport of Diluted Species in the Label text field.

|

|

3

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check boxes for Laminar Flow (spf) and Heat Transfer in Fluids (ht).

|

|

1

|

|

2

|

In the Settings window for Stationary, type Stationary - Heat Transfer in Fluids in the Label text field.

|

|

3

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check boxes for Laminar Flow (spf) and Transport of Diluted Species (tds).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

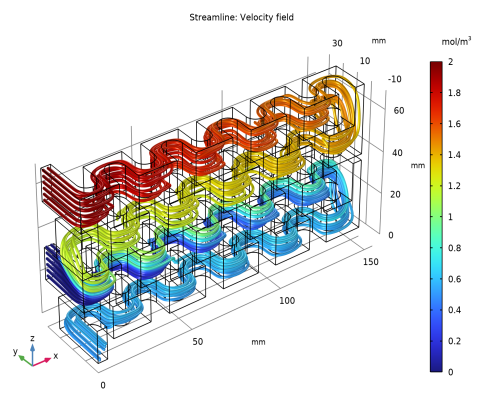

In the Settings window for Color Expression, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species cA>cA - Concentration - mol/m³.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

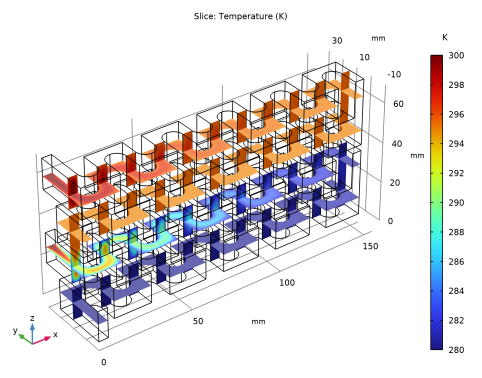

In the Settings window for Slice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

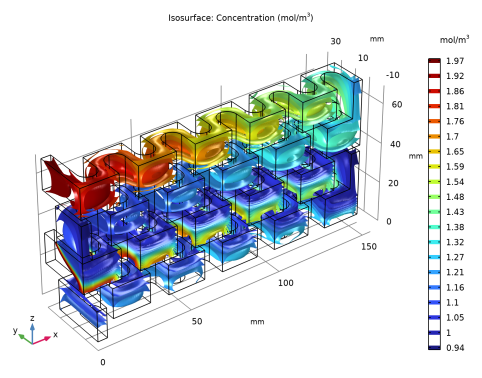

In the Settings window for Isosurface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species cB>cB - Concentration - mol/m³.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

6

|

|

7

|

|

8

|

|

9

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Object to subtract.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Object to subtract.

|

|

5

|

|

1

|

|

2

|

Select the object blk1 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

On the object dif1, select Domain 1 only.

|

|

3

|

|

4

|

|

5

|

On the object dif1, select Boundaries 6 and 54 only.

|

|

6

|

In the tree, select dif1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object pard1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

On the object mir2(1), select Boundary 63 only.

|

|

3

|

On the object mir2(2), select Boundary 63 only.

|

|

4

|

|

6

|

|

1

|

|

2

|

On the object arr2(1,1,1), select Boundary 2 only.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 35 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 34 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 2 only.

|

|

1

|

|

2

|

In the Settings window for Box Selection, type Box Selection - Heat Exchanger 1 in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Box Selection, type Box Selection - Heat Exchanger 2 in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Box Selection, type Box Selection - Heat Exchanger Connection in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Adjacent Selection - Heat Exchanger 1 in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Adjacent Selection - Heat Exchanger 2 in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

Click

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

Click

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Box Selection - Heat Exchanger Connection, Heat Exchanger 1, and Heat Exchanger 2.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Interior boundaries Heat Exchanger 2 in the Label text field.

|

|

3

|

Locate the Input Entities section. In the Input selections list, select Box Selection - Heat Exchanger 1.

|

|

4

|

Click

|

|

5

|

Click

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the Add dialog box, in the Selections to add list, choose Interior boundaries Heat Exchanger 1 and Interior boundaries Heat Exchanger 2.

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|