|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file drug_release_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

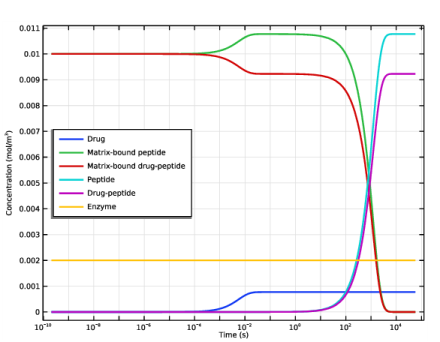

In the Settings window for 1D Plot Group, type Biomaterial Concentrations, 0D model in the Label text field.

|

|

2

|

|

1

|

In the Model Builder window, expand the Biomaterial Concentrations, 0D model node, then click Global 1.

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Select the y-axis label check box. In the associated text field, type Concentration (mol/m<sup>3</sup>).

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics Interfaces section. Find the Chemical species transport subsection. From the list, choose Transport of Diluted Species in Porous Catalysts: New.

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Geometry 1(2Daxi) node, then click Geometry 1(2Daxi).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Chemistry 1 (chem) node, then click Species: d.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Transport of Diluted Species in Porous Catalysts (tds) node, then click Transport of Diluted Species in Porous Catalysts (tds).

|

|

2

|

In the Settings window for Transport of Diluted Species in Porous Catalysts, locate the Transport Mechanisms section.

|

|

3

|

Clear the Convection check box.

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Transport of Diluted Species in Porous Catalysts (tds) click Porous Catalyst 1.

|

|

2

|

|

3

|

|

4

|

Click to collapse the Adsorbed Species section. Locate the Surface Species section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

In the Settings window for Transport Properties, type Transport Properties - Surroundings in the Label text field.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

In the Settings window for Transport Properties, type Transport Properties - Nerve in the Label text field.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 2 (comp2) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Concentration, e, 3D (tds), Concentration, p, 3D (tds), and Concentration, pd, 3D (tds).

|

|

2

|

Right-click and choose Delete.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results>Bulk Concentrations, 3D, Ctrl-click to select Surface 1 and Surface 2.

|

|

2

|

Right-click and choose Duplicate.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results>Bulk Concentrations, 3D, Ctrl-click to select Annotation 1 and Annotation 2.

|

|

2

|

Right-click and choose Duplicate.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Results>Matrix Concentrations, 3D, Ctrl-click to select Surface 3, Surface 4, Annotation 3, and Annotation 4.

|

|

2

|

Right-click and choose Delete.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

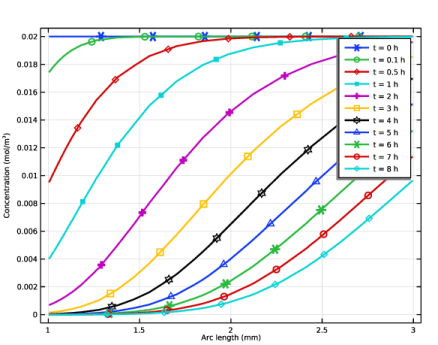

Select the y-axis label check box. In the associated text field, type Concentration (mol/m<sup>3</sup>).

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, right-click Evaluation Group 1 and choose Integration>Surface Integration.

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Animation, type Animation - Matrix Concentrations in the Label text field.

|

|

3

|

|

4

|