|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Batteries>Lithium-Ion Battery, Deformed Geometry.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Time Dependent with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file li_plating_with_deformation_parameters.txt.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

On the object pol1, select Point 1 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

On the object fil1, select Points 3 and 6 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

In the Create Selection dialog box, type Lithium Electrode Surface in the Selection name text field.

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Lithium-Ion Battery (liion) and choose Separator.

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Electrode Properties section. From the σs list, choose User defined. In the associated text field, type sigmas_pos.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Dissolving-Depositing Species section. Use a Dissolving-Depositing Species to define the growth velocity of the lithium electrode surface.

|

|

5

|

Click

|

|

7

|

|

1

|

|

2

|

|

3

|

In the Stoichiometric coefficients for dissolving-depositing species: table, enter the following settings:

|

|

1

|

|

2

|

In the Settings window for Electrode Current, type Electrode Current: Forward Cycle in the Label text field.

|

|

4

|

|

5

|

|

1

|

|

1

|

In the Model Builder window, expand the Multiphysics node, then click Nondeforming Boundary 1 (ndbdg1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click the Custom button.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Study: Forward Cycle node, then click Step 2: Time Dependent.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

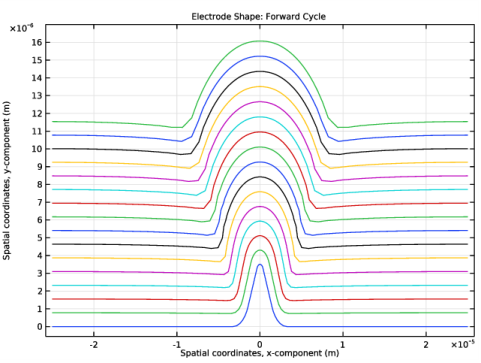

In the Settings window for 1D Plot Group, type Electrode Shape: Forward Cycle in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Select the Loop check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

In the Settings window for Electrode Current, type Electrode Current: Forward and Reverse Cycle in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Lithium-Ion Battery>Time Dependent with Initialization.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

4

|

In the tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current: Forward Cycle.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

6

|

In the tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current: Forward Cycle.

|

|

7

|

Click

|

|

1

|

In the Model Builder window, under Study: Forward Cycle click Step 1: Current Distribution Initialization.

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

4

|

In the tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current: Forward and Reverse Cycle.

|

|

5

|

Click

|

|

1

|

|

2

|

|

4

|

|

5

|

In the tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current: Forward and Reverse Cycle.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

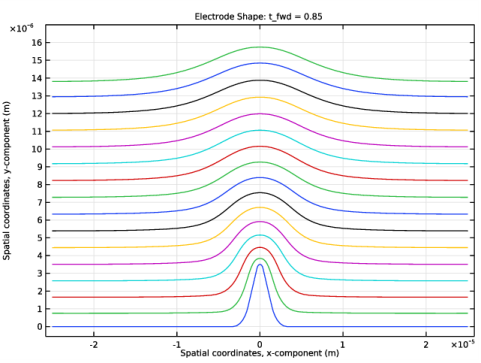

In the Settings window for 1D Plot Group, type Electrode Shape: Forward and Reverse Cycle in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study: Forward and Reverse Cycle/Parametric Solutions 1 (sol5).

|

|

4

|

|

5

|

|

6

|

Click to expand the Title section. In the Title text area, type Electrode Shape: t_fwd = eval(t_fwd).

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|