|

|

1

|

|

2

|

In the Application Libraries window, select Battery Design Module>Batteries, Lithium-Ion>lib_base_model_1d in the tree.

|

|

3

|

Click

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Lithium-Ion Battery (liion) node, then click Electrode Current Density 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Cumulative Energy (ge) click Global Equations 1.

|

|

2

|

|

4

|

|

5

|

In the Dependent variable quantity table, enter the following settings:

|

|

6

|

|

7

|

In the Source term quantity table, enter the following settings:

|

|

1

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 1 and choose Stop Condition.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

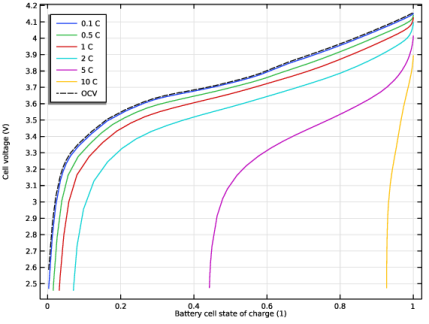

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>E_cell - Point Probe 1 - V.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>E_ocv_cell - Open-circuit cell voltage - V.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

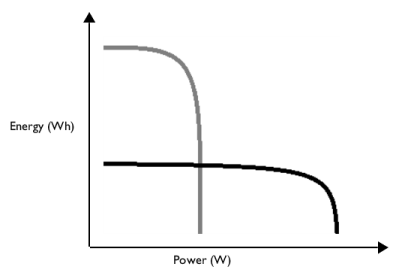

In the Settings window for Global Evaluation, type Ragone Plot Data Evaluation in the Label text field.

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

In the Settings window for Table, type Ragone Plot Data Energy Optimized Cell in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations right-click Parametric Solutions 1 (sol2) and choose Solution>Copy.

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations click Parametric Solutions 1 - Copy 1 (sol9).

|

|

2

|

In the Settings window for Solution, type Parametric Solutions - Energy Optimized Cell in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Ragone Plot Data Evaluation and choose Evaluate>New Table.

|

|

1

|

|

2

|

In the Settings window for Table, type Ragone Plot Data for Power Optimized Cell in the Label text field.

|

|

1

|

In the Model Builder window, under Results>Ragone Plots right-click Table Graph 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|