|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Acoustics>Acoustic-Structure Interaction>Acoustic-Solid Interaction, Transient.

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file loudspeaker_driver_transient_parameters.txt.

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file loudspeaker_driver_transient_geom_sequence.mph.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Select the Cutoff check box.

|

|

6

|

Click to expand the Smoothing section.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Adjacent, type Solid Mechanics Exterior Boundaries in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file loudspeaker_driver_materials.mph.

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

Specify the e vector as

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Transient Solver Settings section. In the Maximum frequency to resolve field enter 3*f0. It will give the maximal time step for the Transient Solver.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Pressure Acoustics, Transient (actd), Solid Mechanics (solid), and Moving mesh (Component 1).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 1 node, then click Automatic Remeshing.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Results>Magnetic Flux Density Norm (mf), Ctrl-click to select Streamline 1 and Contour 1.

|

|

2

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Time Dependent Analysis/Remeshed Solution 1 (sol3).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Time Dependent Analysis/Remeshed Solution 1 (sol3).

|

|

4

|

|

5

|

|

7

|

Locate the Expressions section. In the table, enter the following settings:

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Functions subsection. In the table, enter the following settings:

|

|

5

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Cubic spline.

|

|

6

|

|

7

|

|

8

|

In the Function table, enter the following settings:

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Units section. In the table, enter the following settings:

|

|

9

|

|

10

|

|

11

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1 - Time Dependent Analysis.

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Global ODEs and DAEs (ge) click Global Equations 1.

|

|

2

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check boxes for Magnetic Fields (mf), Pressure Acoustics, Transient (actd), Solid Mechanics (solid), and Moving mesh (Component 1).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check boxes for Magnetic Fields (mf), Pressure Acoustics, Transient (actd), Solid Mechanics (solid), and Moving mesh (Component 1).

|

|

6

|

|

7

|

|

8

|

In the Settings window for Study, type Study 2 - Periodic Signal Extraction and FFT in the Label text field.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Periodic Signal Extraction and FFT/Solution 4 (sol4).

|

|

4

|

From the Parameter selection (freq) list, choose From list, and select all but the first four frequency parameters.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

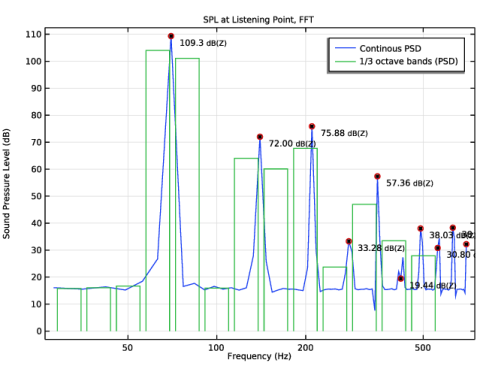

In the Model Builder window, under Results>SPL at Listening Point, FFT right-click Octave Band 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Periodic Signal Extraction and FFT/Solution 4 (sol4).

|

|

4

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Time Dependent Analysis/Remeshed Solution 1 (sol3).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Magnetic Fields>Coil parameters>mf.PCoil_1 - Coil power - W.

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Time Dependent Analysis/Remeshed Solution 1 (sol3).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

On the object c2, select Boundaries 2–4 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object c1 only.

|

|

3

|

|

4

|

|

5

|

Select the object r1 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object r2 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

In the r text field, type 23[mm] 26[mm] 26[mm] 32[mm] 32[mm] 38[mm] 38[mm] 44[mm] 44[mm] 50[mm] 50[mm] 56[mm] 56[mm] 59[mm] 59[mm] 59[mm] 59[mm] 56[mm] 56[mm] 50[mm] 50[mm] 44[mm] 44[mm] 38[mm] 38[mm] 32[mm] 32[mm] 26[mm] 26[mm] 23[mm] 23[mm] 23[mm].

|

|

5

|

In the z text field, type -44.1[mm] -42.1[mm] -42.1[mm] -46.1[mm] -46.1[mm] -42.1[mm] -42.1[mm] -46.1[mm] -46.1[mm] -42.1[mm] -42.1[mm] -46.1[mm] -46.1[mm] -44.1[mm] -44.1[mm] -44.5[mm] -44.5[mm] -46.5[mm] -46.5[mm] -42.5[mm] -42.5[mm] -46.5[mm] -46.5[mm] -42.5[mm] -42.5[mm] -46.5[mm] -46.5[mm] -42.5[mm] -42.5[mm] -44.5[mm] -44.5[mm] -44.1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

1

|

|

2

|

On the object uni2, select Boundaries 13, 19, 33, and 45 only.

|

|

1

|

|

2

|

On the object del2, select Points 14, 15, 35, and 36 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

On the object fin, select Points 18, 26, and 33 only.

|

|

3

|