|

•

|

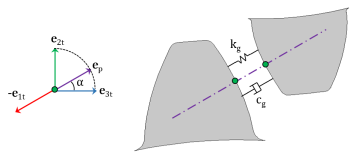

kg is the mesh stiffness of gear pair

|

|

•

|

cg is the mesh damping of gear pair

|

|

•

|

rpn is the pitch radius of pinion

|

|

•

|

wpn is the working width of pinion

|

|

The mesh stiffness expressions in this section are derived for a Gear Pair node.

To get equations that are specific to the Worm and Wheel node, replace “wheel” with “worm” and “pinion” with “wheel” everywhere.

To get equations that are specific to the Rack and Pinion node, replace “wheel” with “rack” everywhere.

|

|

•

|

kt,wh is the gear tooth stiffness as function of mesh cycle

|

|

•

|

θm,wh is the mesh cycle

|

|

•

|

|

•

|