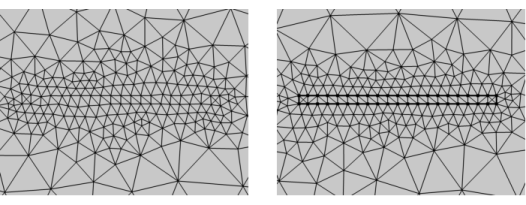

The most straightforward way to control the mesh size in a part of a domain or on part of a boundary is to partition the geometry in such a way that a mesh Size can be assigned on the entity in question. However, the additional domain, face, or curve is typically not wanted when assigning materials and physics. Mark the additional entity as a mesh control entity to remove it from the view once it has been meshed.

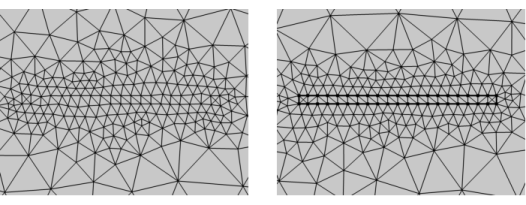

For example, add a rectangle inside a 2D domain to resolve the mesh inside the rectangle (see right image in Figure 8-14). Mark the resulting edges as a mesh control entity to remove it from the geometry when defining the physics and materials. An advantage is that the final mesh need not respect the mesh control edges exactly; it is used only to control element size and then the mesh is smoothed, as shown in the left image below.