|

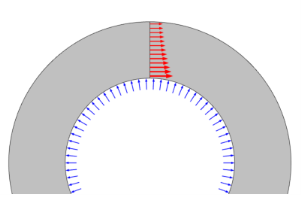

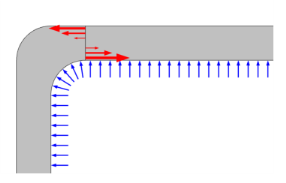

The pressure p here is the gauge pressure, assumed to be positive. If the pressure in the pipe is given as an absolute pressure, then the external pressure (usually 1 atm) must also be supplied. It is assumed that the external pressure is small relative to the internal pressure, so that the stress distribution through the pipe wall is given only by the gauge pressure p = pinternal - pexternal.

|