|

|

1

|

|

2

|

In the Select Physics tree, select Optics>Wave Optics>Electromagnetic Waves, Frequency Domain (ewfd).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file photonic_crystal_demultiplexer_optimization_geom_sequence.mph.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the tree, select Optical>Inorganic Materials>As - Arsenides>Experimental data>GaAs (Gallium arsenide) (Skauli et al. 2003: n 0.97-17 um).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Electromagnetic Waves, Frequency Domain (ewfd).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Scattering Boundary Condition section. From the Incident field list, choose Wave given by E field.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click Section toolbar in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Electromagnetic Waves, Frequency Domain>Energy and power>ewfd.nPoav - Power outflow, time average - W/m².

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Locate the Parameters section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Translation section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Electromagnetic Waves, Frequency Domain>ewfd.lambda0 - Wavelength in free space - m.

|

|

5

|

Locate the Expression section. In the Expression text field, type if(ewfd.lambda0<(lambda1+lambda2)/2,obj1/obj2,obj2/obj1).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Wavelength Domain.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Wavelengths text field, type range(lambda1-dWave/2,dWave/(dWaveN-1),lambda1+dWave/2) range(lambda2-dWave/2,dWave/(dWaveN-1),lambda2+dWave/2).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 1 (comp1)>Definitions>comp1.obj - Objective Function.

|

|

6

|

|

7

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 1 (comp1)>Definitions>comp1.constr - Constraint.

|

|

8

|

Locate the Constraints section. In the table, enter the following settings:

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

Select the Plot check box.

|

|

16

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Shape Optimization>Solver Configurations>Solution 2 (sol2)>Optimization Solver 1>Stationary 1 node.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

In the Add dialog box, in the Variables list, choose Electric field (spatial and material frames) (comp1.E) and Translation (geometry frame) (comp1.tsf1.move).

|

|

15

|

Click OK.

|

|

16

|

|

1

|

|

2

|

Right-click Results>Datasets>Shape Optimization/Solution 2 (sol2) and choose Remesh Deformed Configuration.

|

|

1

|

|

2

|

|

3

|

Click to expand the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

10

|

|

12

|

|

13

|

|

14

|

|

15

|

|

1

|

|

2

|

|

1

|

|

2

|

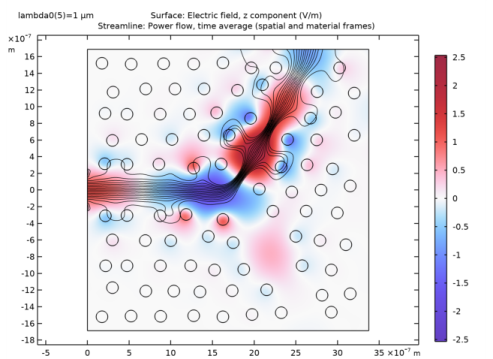

In the Settings window for Surface, click Section toolbar in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Electromagnetic Waves, Frequency Domain>Electric>Electric field - V/m>ewfd.Ez - Electric field, z component.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Electromagnetic Waves, Frequency Domain>Energy and power>ewfd.Poavx,ewfd.Poavy - Power flow, time average (spatial and material frames).

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Surface, click Section toolbar in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Electromagnetic Waves, Frequency Domain>Electric>Electric field (spatial and material frames) - V/m>ewfd.Ez - Electric field, z component.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type P (nW/m).

|

|

7

|

|

1

|

|

2

|

In the Settings window for Global, click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>obj1 - Power port 1 - W/m.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>obj2 - Power port 2 - W/m.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Thumbnail>Translation (Transformation 1) node, then click Results>Thumbnail>Line 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Deformation, click Section toolbar in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Transformation 1>tsf1.dXg,tsf1.dYg - Boundary displacement (geometry frame).

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Results>Thumbnail>Translation (Transformation 1) click Color Expression 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Position section. In the y text field, type -2*dPeriod*sin(pi/3)*round(H/dPeriod/sin(pi/3)/3).

|

|

5

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click

|

|

10

|

|

11

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

Click

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Circles to Delete, row1 (boxsel2) and choose Duplicate.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Circles to Delete, row2 (boxsel3) and choose Duplicate.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Circles to Delete, Circles to Delete, row1, Circles to Delete, row2, and Circles to Delete, row3.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|