|

|

•

|

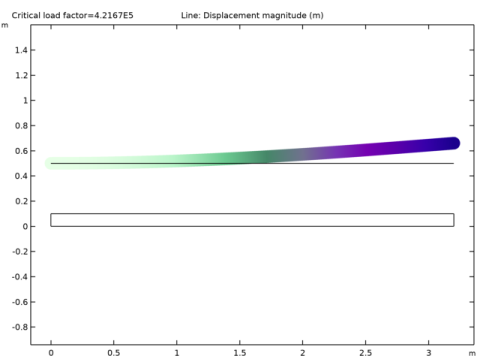

The length of the beam is 3.2 m.

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file large_deformation_beam_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

10

|

|

1

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1) node, then click Stationary Solver 1.

|

|

2

|

|

3

|

|

4

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node.

|

|

5

|

|

6

|

|

7

|

|

8

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1>Segregated 1 node, then click Segregated Step.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

Click to expand the Method and Termination section. From the Termination technique list, choose Tolerance.

|

|

14

|

|

15

|

|

16

|

|

17

|

In the Add dialog box, in the Variables list, choose Rotation field (material and geometry frames) (comp1.beam.thLin) and Displacement field (material and geometry frames) (comp1.beam.uLin).

|

|

18

|

Click OK.

|

|

19

|

|

20

|

|

21

|

|

22

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>u - Displacement field, X component.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>v - Displacement field, Y component.

|

|

3

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Displacement field - m>u2 - Displacement field, X component.

|

|

7

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Displacement field - m>v2 - Displacement field, Y component.

|

|

3

|

Locate the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Circle.

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Tip displacement.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>u - Displacement field, X component.

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Point Evaluation 1 and choose Duplicate.

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Point Evaluation 2 and choose Duplicate.

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Point Evaluation 3 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Point Evaluation 4 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Linear Buckling.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

8

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

6

|

Click

|