|

|

•

|

|

•

|

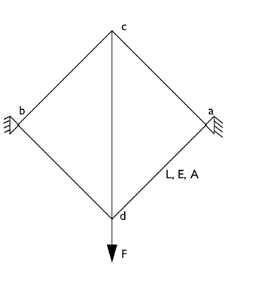

The truss members have a circular cross section with a radius of 0.05 m. In the 3D case, the area of the central bar is doubled.

|

|

-5.14·10-4 m

|

-5.15·10-4 m

|

|

|

-2.13·10-4 m

|

-2.13·10-4 m

|

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Material properties tree, select Solid Mechanics>Linear Elastic Material>Young’s Modulus and Poisson’s Ratio.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Displacement of Vertices (2D) in the Label text field.

|

|

1

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Axial Force in Members (2D) in the Label text field.

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Truss (truss).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the object wp1 only.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Displacement of Vertices (3D) in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Displacement of Vertices (3D) node, then click Point Evaluation 1.

|

|

3

|

|

5

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Axial Force in Members (3D) in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Axial Force in Members (3D) node, then click Global Evaluation 1.

|

|

2

|

|

4

|