|

|

1

|

|

2

|

In the Application Libraries window, select Structural Mechanics Module>Tutorials>bracket_basic in the tree.

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Random Vibration (PSD).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

In the tree, select Component 1 (Comp1)>Solid Mechanics (Solid)>Linear Elastic Material 1>Damping 1.

|

|

5

|

Right-click and choose Disable.

|

|

1

|

In the Model Builder window, expand the Global Definitions>Reduced-Order Modeling node, then click Global Reduced Model Inputs 1.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the Settings window for Rigid Connector, locate the Prescribed Displacement at Center of Rotation section.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

Specify the F vector as

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

In the Model Builder window, expand the Step 1: Model Reduction node, then click Frequency Domain 1.

|

|

2

|

|

3

|

|

1

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file bracket_random_vibration_log.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Intervals subsection. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Find the Intervals subsection. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Global Definitions>Reduced-Order Modeling click Random Vibration 1 (rvib1).

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

6

|

Click

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

6

|

Click

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Frequnecy [Hz].

|

|

5

|

|

6

|

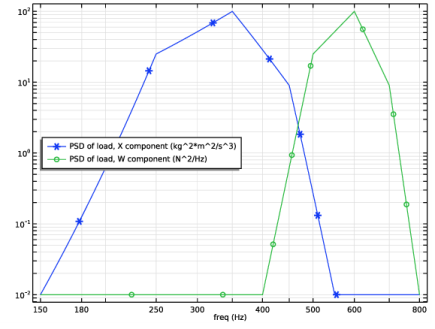

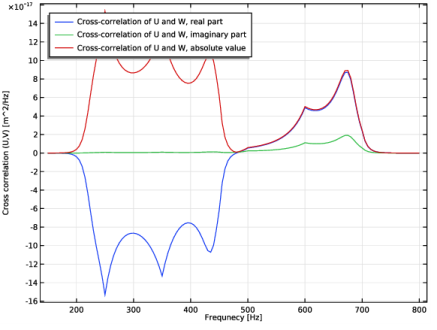

In the associated text field, type Cross correlation (U,V) [m^2/Hz].

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

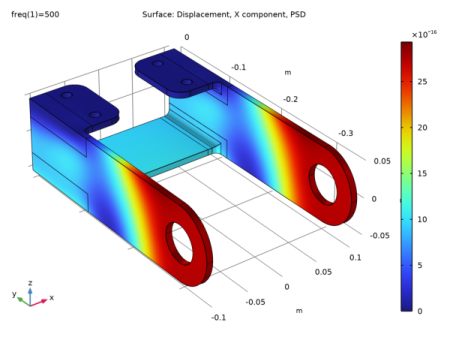

In the associated text field, type Displacement, X component, PSD.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Stress, von Mises, RMS.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

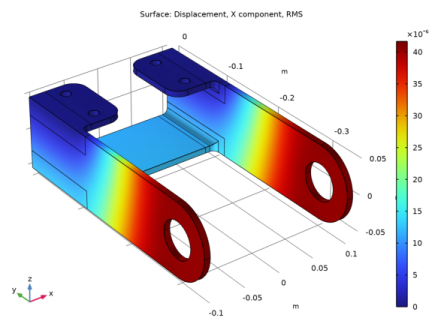

In the associated text field, type Displacement, magnitude, RMS.

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Acceleration, magnitude, RMS.

|

|

6

|