|

|

1

|

|

2

|

In the Application Libraries window, select Structural Mechanics Module>Tutorials>bracket_basic in the tree.

|

|

3

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Units section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Boundary Load.

|

|

2

|

|

3

|

|

4

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Boundary System 1 (sys1).

|

|

5

|

|

1

|

|

2

|

|

3

|

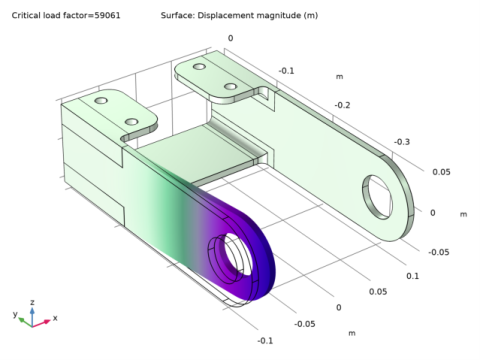

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Linear Buckling.

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 2>Solver Configurations>Solution 3 (sol3)>Stationary Solver 1 node.

|

|

4

|

Right-click Study 2>Solver Configurations>Solution 3 (sol3)>Stationary Solver 1>Parametric 1 and choose Stop Condition.

|

|

5

|

|

6

|

Click

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

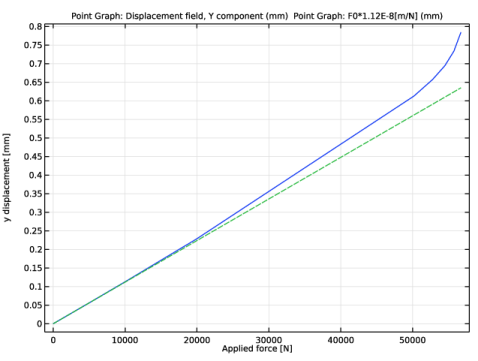

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Applied force [N].

|

|

5

|

|

6

|

In the associated text field, type y displacement [mm].

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

7

|