|

|

1

|

|

2

|

In the Application Libraries window, select Structural Mechanics Module>Tutorials>bracket_basic in the tree.

|

|

3

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

In the Function table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Units section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Global ODEs and DAEs (ge) click Global Equations 1.

|

|

2

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Settings window for Study, type Study 1: Fourier Coefficient Generation in the Label text field.

|

|

2

|

|

1

|

In the Model Builder window, under Study 1: Fourier Coefficient Generation click Step 1: Time Dependent.

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check box for Solid Mechanics (solid).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check box for Solid Mechanics (solid).

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Study 1: Fourier Coefficient Generation>Solver Configurations>Solution 1 (sol1) node.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

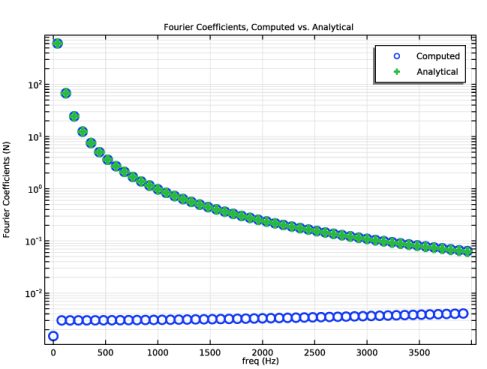

In the Settings window for 1D Plot Group, type Fourier Coefficients, Computed vs. Analytical in the Label text field.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the associated text field, type freq (Hz).

|

|

9

|

|

10

|

In the associated text field, type Fourier Coefficients (N).

|

|

11

|

|

1

|

|

2

|

|

4

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 1: Fourier Coefficient Generation/Solution 1 (sol1).

|

|

5

|

|

6

|

|

7

|

Locate the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Plus sign.

|

|

8

|

Locate the Legends section. In the table, enter the following settings:

|

|

9

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Fourier Coefficients; Real and Imaginary in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

In the associated text field, type freq (Hz).

|

|

10

|

|

11

|

In the associated text field, type Fourier Coefficients (N).

|

|

1

|

|

2

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Solid Mechanics>Frequency Domain, Modal.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Study 2: Frequency Domain Modal + FFT click Step 1: Eigenfrequency.

|

|

2

|

|

3

|

|

5

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

6

|

In the tree, select Component 1 (Comp1)>Solid Mechanics (Solid)>Linear Elastic Material 1>Damping 1.

|

|

7

|

Right-click and choose Disable.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Stress: Frequency Domain Modal + FFT node, then click Volume 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Displacement Amplitude [Frequency Response] in the Label text field.

|

|

3

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 2: Frequency Domain Modal + FFT/Solution Store 3 (sol5).

|

|

5

|

|

6

|

|

1

|

|

3

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement amplitude (material and geometry frames) - m>solid.uAmpX - Displacement amplitude, X component.

|

|

4

|

|

5

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for Boundary Load, type Boundary Load, Time Domain Amplitude in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Study 2: Frequency Domain Modal + FFT click Step 2: Frequency Domain, Modal.

|

|

2

|

In the Settings window for Frequency Domain, Modal, locate the Physics and Variables Selection section.

|

|

3

|

In the tree, select Component 1 (Comp1)>Solid Mechanics (Solid)>Boundary Load, Time Domain Amplitude.

|

|

4

|

Right-click and choose Disable.

|

|

1

|

|

2

|

In the Settings window for Frequency to Time FFT, locate the Physics and Variables Selection section.

|

|

3

|

In the tree, select Component 1 (Comp1)>Solid Mechanics (Solid)>Boundary Load, Time Domain Amplitude.

|

|

4

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Solid Mechanics>Time Dependent, Modal.

|

|

4

|

|

5

|

|

1

|

In the Settings window for Study, type Study 3: Time-Dependent Modal [Verification] in the Label text field.

|

|

1

|

In the Model Builder window, under Study 3: Time-Dependent Modal [Verification] click Step 1: Time Dependent, Modal.

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

|

6

|

Right-click and choose Disable.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

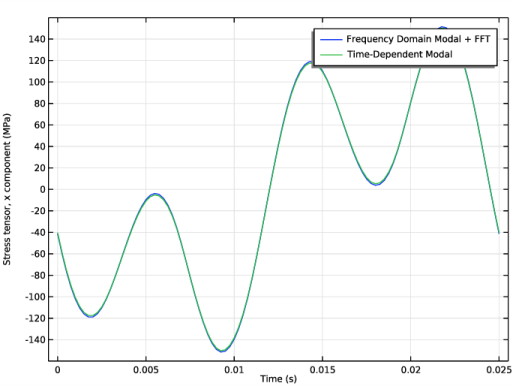

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

|

8

|