|

|

1

|

|

2

|

In the Application Libraries window, select Structural Mechanics Module>Tutorials>bracket_basic in the tree.

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Materials node, then click Structural steel (mat1).

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Frequency Domain, Modal.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Frequency (Hz).

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Displacement phase, X component in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Frequency (Hz).

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement phase (material and geometry frames) - rad>solid.uPhaseX - Displacement phase, X component.

|

|

5

|

|

6

|

|

7

|

|

9

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Frequency Domain, Prestressed.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Units section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Boundary System 1 (sys1).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

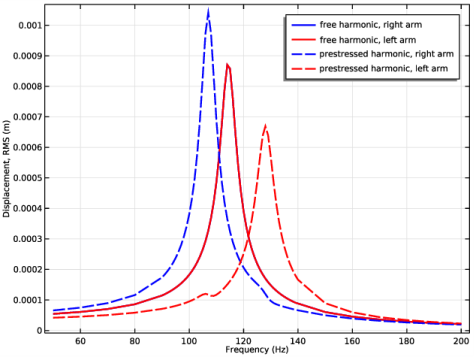

In the Model Builder window, under Results>Displacement, RMS, Ctrl-click to select Point Graph 1 and Point Graph 2.

|

|

2

|

Right-click and choose Duplicate.

|

|

1

|

|

2

|

|

3

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

5

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Cut Point 3D 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Displacement phase, X component right-click Point Graph 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|