|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Rotordynamics>Solid Rotor with Hydrodynamic Bearing.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file reciprocating_engine_rotor.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Select the Cutoff check box.

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

In the text field, type Ow*rm1(Ow*t/2).

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Rotor (rotsld) click Linear Elastic Material 1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Rotor (rotsld)>Rotor Axis 1 click First Support 1.

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Rotor (rotsld) click Fixed Axial Rotation 1.

|

|

1

|

|

1

|

|

1

|

In the Model Builder window, expand the Thrust Bearing 2 node, then click Component 1 (comp1)>Hydrodynamic Bearing (hdb).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrodynamic Bearing (hdb) click Hydrodynamic Journal Bearing 1.

|

|

2

|

|

3

|

|

4

|

Locate the Fluid Properties section. From the μ list, choose User defined. In the associated text field, type mu_l.

|

|

5

|

|

1

|

Right-click Component 1 (comp1)>Hydrodynamic Bearing (hdb)>Hydrodynamic Journal Bearing 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 1 node, then click Pressure (comp1.pfilm).

|

|

4

|

|

5

|

|

6

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 1 node, then click Fully Coupled 1.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

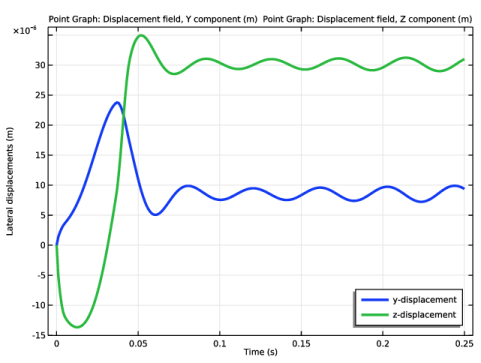

In the associated text field, type y-displacement.

|

|

6

|

|

7

|

In the associated text field, type z-displacement.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Lateral displacements (m).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|