|

|

Density ρ

|

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object cyl1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

Repeat above sequence of commands to add more Explicit selections using the information given in the following table:

|

|

2

|

|

1

|

|

2

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

3

|

In the tree, select Physics>Stabilization.

|

|

4

|

In the tree, select the check box for the node Physics>Stabilization.

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

Select the Cavitation check box.

|

|

9

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrodynamic Bearing (hdb) click Hydrodynamic Journal Bearing 1.

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (Plain) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Fluid Properties section. From the μ list, choose User defined. In the associated text field, type mu.

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (Elliptic) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (Split halves) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (2-lobe) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (3-lobe LOP) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (3-lobe LBP) in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (4-lobe LOP) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Journal Bearing, type Hydrodynamic Journal Bearing (4-lobe LBP) in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Bearing Orientation, type Bearing Orientation Hydrodynamic Journal Bearing (3-lobe LOP) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Bearing Orientation, type Bearing Orientation Hydrodynamic Journal Bearing (3-lobe LBP) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Bearing Orientation, type Bearing Orientation Hydrodynamic Journal Bearing (4-lobe LOP) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

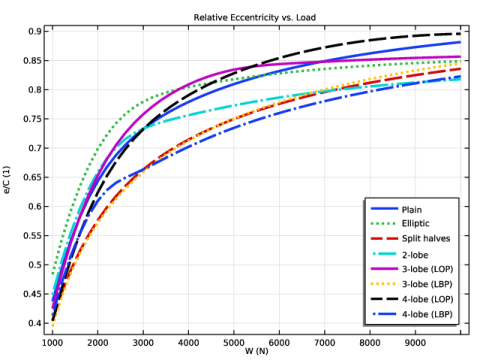

In the Settings window for 1D Plot Group, type Relative Eccentricity vs. Load in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the associated text field, type e/C (1).

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (Plain)>Eccentricity and attitude angle>hdb.hjb1.ec_rel - Relative eccentricity.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (Elliptic)>Eccentricity and attitude angle>hdb.hjb2.ec_rel - Relative eccentricity.

|

|

4

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (Split halves)>Eccentricity and attitude angle>hdb.hjb3.ec_rel - Relative eccentricity.

|

|

5

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (2-lobe) >Eccentricity and attitude angle>hdb.hjb4.ec_rel - Relative eccentricity.

|

|

6

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (3-lobe LOP)>Eccentricity and attitude angle>hdb.hjb5.ec_rel - Relative eccentricity.

|

|

7

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (3-lobe LBP)>Eccentricity and attitude angle>hdb.hjb6.ec_rel - Relative eccentricity.

|

|

8

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (4-lobe LOP)>Eccentricity and attitude angle>hdb.hjb7.ec_rel - Relative eccentricity.

|

|

9

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (4-lobe LBP)>Eccentricity and attitude angle>hdb.hjb8.ec_rel - Relative eccentricity.

|

|

10

|

|

11

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the associated text field, type \phi (degree).

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (Plain)>Eccentricity and attitude angle>hdb.hjb1.phia - Attitude angle - rad.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (Elliptic)>Eccentricity and attitude angle>hdb.hjb2.phia - Attitude angle - rad.

|

|

4

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (Split halves)>Eccentricity and attitude angle>hdb.hjb3.phia - Attitude angle - rad.

|

|

5

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (2-lobe) >Eccentricity and attitude angle>hdb.hjb4.phia - Attitude angle - rad.

|

|

6

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (3-lobe LOP)>Eccentricity and attitude angle>hdb.hjb5.phia - Attitude angle - rad.

|

|

7

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (3-lobe LBP)>Eccentricity and attitude angle>hdb.hjb6.phia - Attitude angle - rad.

|

|

8

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (4-lobe LOP)>Eccentricity and attitude angle>hdb.hjb7.phia - Attitude angle - rad.

|

|

9

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing (4-lobe LBP)>Eccentricity and attitude angle>hdb.hjb8.phia - Attitude angle - rad.

|

|

10

|

|

11

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

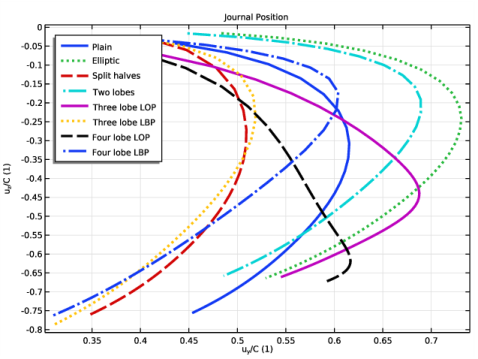

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type u<sub>y</sub>/C (1).

|

|

6

|

|

7

|

In the associated text field, type u<sub>z</sub>/C (1).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

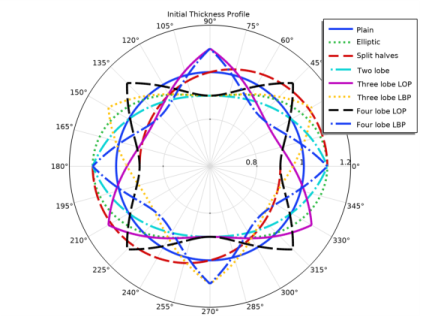

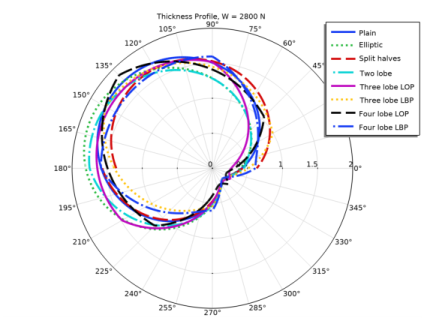

In the Settings window for Polar Plot Group, type Initial Thickness Profile in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the r-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Journal and bearing properties>Film thickness and clearance>hdb.hi_rel - Relative film thickness, initial.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

9

|

|

10

|

|

11

|

|

13

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Polar Plot Group, type Current Thickness Profile in the Label text field.

|

|

3

|

|

4

|

|

1

|

Edit the existing Line Graph nodes under Polar: Current Thickness Profile using the information given in the following table:

|

|

2

|

In the Model Builder window, expand the Current Thickness Profile node, then click Results>Current Thickness Profile.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|