|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

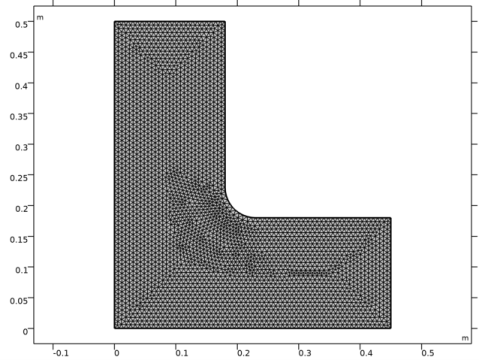

Browse to the model’s Application Libraries folder and double-click the file loaded_knee_geom_sequence.mph.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Physics Utilities>Mass Properties.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose More Materials>Topology Link.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

1

|

In the Model Builder window, expand the Results>Topology Optimization node, then click Output material volume factor.

|

|

2

|

In the Settings window for 2D Plot Group, type Penalized Material Volume Factor in the Label text field.

|

|

1

|

In the Model Builder window, expand the Penalized Material Volume Factor node, then click Surface 1.

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Density Model 1>Auxiliary variables>dtopo1.theta_p - Penalized material volume factor.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Settings window for Global Evaluation, click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Global>solid.Ws_tot - Total elastic strain energy - J.

|

|

4

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global Variable Probe, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Density Model 1>Global>dtopo1.theta_avg - Average material volume factor.

|

|

3

|

|

4

|

In the associated text field, type Solid fraction.

|

|

1

|

|

2

|

In the Settings window for Global Variable Probe, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Global>solid.Ws_tot - Total elastic strain energy - J.

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Strain energy factor.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 1 (comp1)>Definitions>Density Model 1>Global>comp1.dtopo1.theta_avg - Average material volume factor.

|

|

5

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Global>comp1.solid.Ws_tot - Total elastic strain energy - J.

|

|

6

|

Locate the Constraints section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

6

|

Click to expand the Advanced Settings section. Select the Reuse solution from previous step check box.

|

|

7

|