|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file two_stage_compaction_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

In the Function table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Aluminum.

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Revolution 2D 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Revolution 2D 2 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets, Ctrl-click to select Study: Two-Stage Compaction/Solution 1 (3) (sol1), Revolution 2D 3, Study: Single-Stage Compaction/Solution 2 (4) (sol2), and Revolution 2D 4.

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Stress, Two-Stage Compaction in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Settings window for 2D Plot Group, type Stress, Single-Stage Compaction in the Label text field.

|

|

4

|

Locate the Data section. From the Dataset list, choose Study: Single-Stage Compaction/Solution 2 (2) (sol2).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Relative Density, Two-Stage Compaction in the Label text field.

|

|

1

|

In the Model Builder window, expand the Relative Density, Two-Stage Compaction node, then click Surface 1.

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Porous plasticity>solid.lemm1.popl1.rhorel - Current relative density.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, right-click Relative Density, Two-Stage Compaction and choose Duplicate.

|

|

2

|

Drag and drop Relative Density, Two-Stage Compaction 1 below Relative Density, Two-Stage Compaction.

|

|

3

|

In the Settings window for 3D Plot Group, type Relative Density, Single-Stage Compaction in the Label text field.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Relative Density, Single-Stage Compaction node, then click Surface 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Relative Density, Single-Stage Compaction>Surface 1 click Deformation.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results>Relative Density, Single-Stage Compaction click Surface 2.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Relative Density, Single-Stage Compaction>Surface 2 click Deformation.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

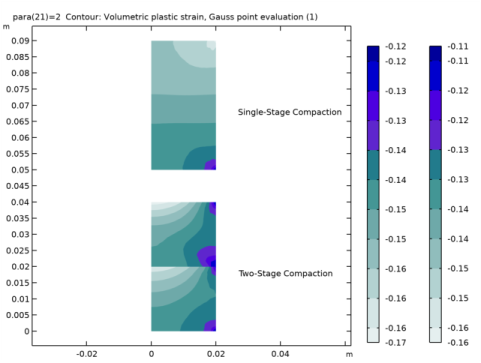

Locate the Expression section. In the Expression text field, type if(isnan(solid2.epvol),NaN,solid2.epvol).

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Average Elastic Volumetric Strain, Two-Stage Compaction in the Label text field.

|

|

1

|

Right-click Average Elastic Volumetric Strain, Two-Stage Compaction and choose Average>Surface Average.

|

|

3

|

|

1

|

In the Model Builder window, right-click Average Elastic Volumetric Strain, Two-Stage Compaction and choose Average>Surface Average.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Average Elastic Volumetric Strain, Two-Stage Compaction in the Label text field.

|

|

3

|

|

4

|

In the associated text field, type Average Elastic Volumetric Strain.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, right-click Average Elastic Volumetric Strain, Two-Stage Compaction and choose Annotation.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

In the Settings window for 1D Plot Group, type Punch Force Vs. Axial Compaction in the Label text field.

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Punch Force (kN).

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|