|

|

•

|

|

•

|

Plastic properties: Yield stress 243 MPa and a linear isotropic hardening with tangent modulus 2171 MPa.

|

|

•

|

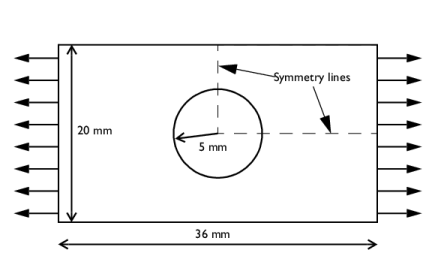

The right vertical edge is subjected to a stress, which increases from zero to a maximum value of 133.65 MPa and then is released. The peak value is selected so that the mean stress over the section through the hole is 10% above the yield stress (=1.1·243·(20−10)/20). The complete release of the stress corresponds to a parameter value of 2.2, see Figure 2.

|

|

•

|

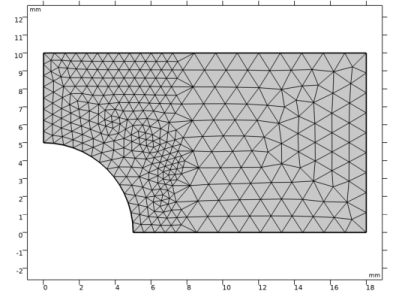

In Study 1, a plate that uses triangular mesh elements is used, see Figure 3. The plate is loaded, and then released using the prescribed stress on the right vertical edge, see Figure 2.

|

|

•

|

In Study 2, a plate that uses quadrilateral mesh elements is used, see Figure 4. This study is started from an intermediate stage, corresponding to a parameter value of 0.8, see Figure 2. The displacements and plastic strains from the plate in Study 1 are mapped onto the plate in Study 2..

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

Select the object c1 only.

|

|

6

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

In the Model Builder window, under Global Definitions>Materials>Material 1 (mat1) click Basic (def).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

11

|

|

12

|

|

13

|

Click OK.

|

|

14

|

|

16

|

|

17

|

|

18

|

Click OK.

|

|

19

|

|

21

|

|

22

|

|

23

|

|

24

|

|

25

|

In the Material properties tree, select Solid Mechanics>Elastoplastic Material>Elastoplastic Material Model.

|

|

26

|

|

27

|

In the Model Builder window, under Global Definitions>Materials>Material 1 (mat1) click Elastoplastic material model (ElastoplasticModel).

|

|

28

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

In the Function table, enter the following settings:

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Plastic Region, Triangular Mesh in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Solid Mechanics 2 (solid2)>Linear Elastic Material 1>Plasticity 1 click Set Variables 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click to expand the Values of Dependent Variables section. Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

|

5

|

|

6

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

Click

|

|

13

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Equivalent Plastic Strain (solid2) node, then click Equivalent Plastic Strain (solid2).

|

|

2

|

In the Settings window for 2D Plot Group, type Plastic Region, Quadrilateral Mesh in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|