|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file orthotropic_container_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Select the object c2 only.

|

|

4

|

Locate the Difference section. Find the Objects to subtract subsection. Click to select the

|

|

5

|

Select the object c1 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object c3 only.

|

|

3

|

|

4

|

|

5

|

Select the object c4 only.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2 node.

|

|

4

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2>Parametric 1 and choose Stop Condition.

|

|

5

|

|

6

|

Click

|

|

8

|

|

9

|

|

1

|

|

2

|

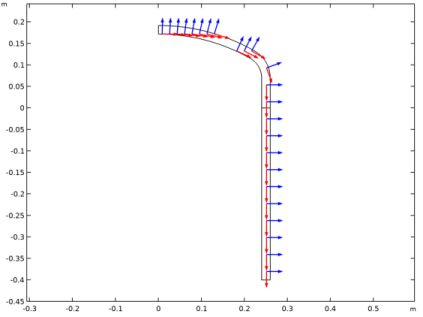

In the Settings window for 2D Plot Group, type Material Principal Direction in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Clear the Unit check box.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|