|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file arterial_wall_mechanics_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file arterial_wall_mechanics_pressure_radius.txt.

|

|

6

|

|

7

|

Click

|

|

8

|

Find the Functions subsection. In the table, enter the following settings:

|

|

9

|

|

10

|

In the Function table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

In the Settings window for Rotated System, type Rotated System Media Fiber Family 1 in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Rotated System, type Rotated System Media Fiber Family 2 in the Label text field.

|

|

3

|

Locate the Rotation section. Find the Euler angles (Z-X-Z) subsection. In the β text field, type -betaM.

|

|

1

|

|

2

|

In the Settings window for Rotated System, type Rotated System Adventitia Fiber Family 1 in the Label text field.

|

|

3

|

Locate the Rotation section. Find the Euler angles (Z-X-Z) subsection. In the β text field, type betaA.

|

|

1

|

|

2

|

In the Settings window for Rotated System, type Rotated System Adventitia Fiber Family 2 in the Label text field.

|

|

3

|

Locate the Rotation section. Find the Euler angles (Z-X-Z) subsection. In the β text field, type -betaA.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

From the list, choose Quasistatic.

|

|

1

|

|

2

|

In the Settings window for Hyperelastic Material, type Hyperelastic Material (Media) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Hyperelastic Material, type Hyperelastic Material (Adventita) in the Label text field.

|

|

4

|

Locate the Hyperelastic Material section. From the Compressibility list, choose Incompressible material.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Rotated System Media Fiber Family 1 (sys2).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Rotated System Media Fiber Family 2 (sys3).

|

|

1

|

|

2

|

|

3

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Rotated System Adventitia Fiber Family 1 (sys4).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Rotated System Adventitia Fiber Family 2 (sys5).

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

Click

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Parametric 1.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Study 1/Solution 1 (sol1) and choose Duplicate.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Advanced section.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Revolution 2D, type Adventitia Sector Revolution in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

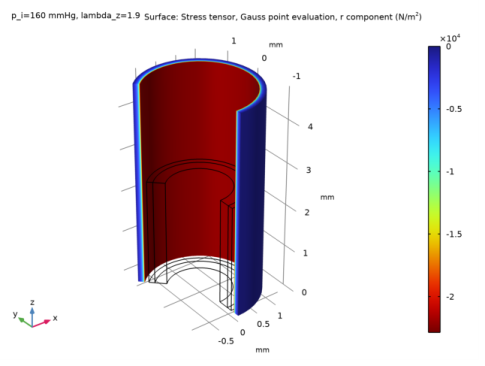

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress (Gauss points)>Stress tensor, Gauss point evaluation (spatial frame) - N/m²>solid.sGpr - Stress tensor, Gauss point evaluation, r component.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Inner radius (mm).

|

|

6

|

|

7

|

In the associated text field, type Internal pressure (mmHg).

|

|

8

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Geometry>Coordinate (spatial frame)>r - r-coordinate.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Define custom colors.

|

|

10

|

Click Add to custom colors.

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

Click Add to custom colors.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Locate the Coloring and Style section. Find the Point style subsection. From the Color list, choose Blue.

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Coloring and Style section. Find the Point style subsection. From the Color list, choose Red.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|