|

|

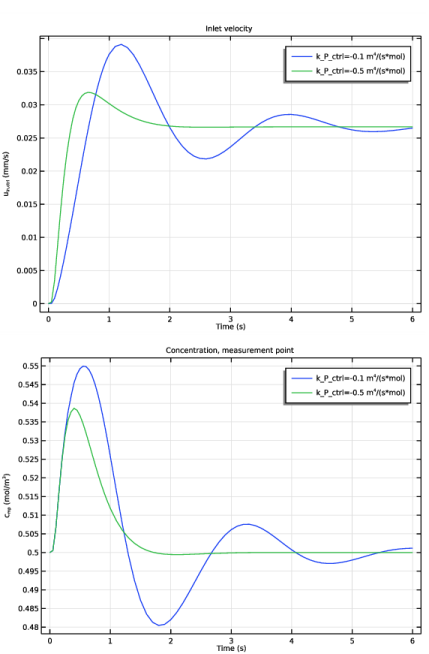

-0.5 m4/(mol·s)

|

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

-0.5 m4/(s·mol)

|

|||

|

-1 m4/(s²·mol)

|

|||

|

-0.001 m4/mol

|

|

1

|

|

2

|

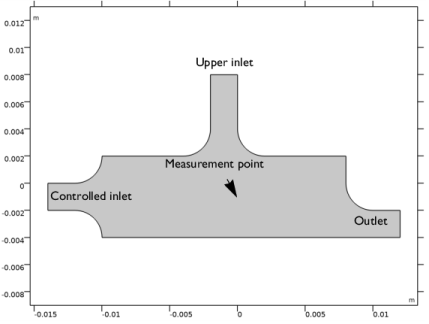

Browse to the model’s Application Libraries folder and double-click the file pid_control_geom_sequence.mph.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Domain Point Probe 1 node, then click Point Probe Expression 1 (ppb1).

|

|

2

|

|

3

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species c>c - Concentration - mol/m³.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Add-in Libraries window, in the tree, select the check box for the node COMSOL Multiphysics>pid_controller (if it is not already selected).

|

|

2

|

Click

|

|

1

|

|

2

|

|

4

|

Click Create.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Laminar Flow (spf) and choose Inlet.

|

|

3

|

|

4

|

In the U0 text field, type comp2.u_in_ctrl. This is the inlet velocity defined by the PID controller.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>u,v - Velocity field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type u<sub>in,ctrl</sub> (mm/s).

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 2 (comp2)>Definitions>Variables>comp2.u_in_ctrl - Control variable - m/s.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Concentration, Measurement Point in the Label text field.

|

|

3

|

|

4

|

Locate the Plot Settings section. In the y-axis label text field, type c<sub>mp</sub> (mol/m<sup>3</sup>).

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>c_mp - Domain Point Probe 1, c - mol/m³.

|

|

3

|