|

|

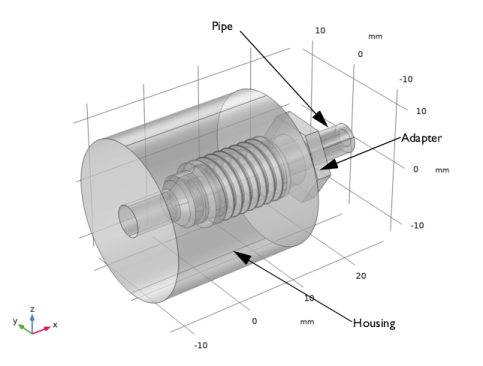

Faceset1.pipe

|

pipe.ipt

|

|

|

Faceset2.pipe

|

pipe.ipt

|

|

|

Faceset1.adaptor

|

adaptor.ipt

|

|

|

Faceset2.adaptor

|

adaptor.ipt

|

|

|

adaptor.ipt

|

||

|

Faceset1.housing

|

housing.ipt

|

|

|

Faceset2.housing

|

housing.ipt

|

|

|

1

|

In Inventor open the file pipe_fitting_cad/pipe_fitting.iam located in the model’s Application Library folder.

|

|

3

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click Synchronize.

|

|

4

|

Click to expand the Object Selections section. Click to expand the Boundary Selections section. The selections listed in these sections are defined on the geometry in the Inventor assembly. For more details see Notes About the COMSOL Implementation.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

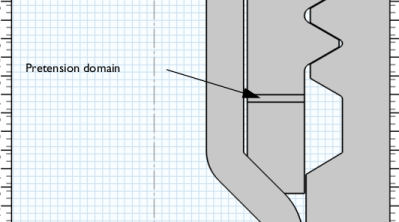

Locate the Destination Boundaries section. From the Selection list, choose Faceset2.adaptor (Cross Section 1).

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Destination Boundaries section. From the Selection list, choose Faceset1.adaptor (Cross Section 1).

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Destination Boundaries section. From the Selection list, choose Faceset1.pipe (Cross Section 1).

|

|

1

|

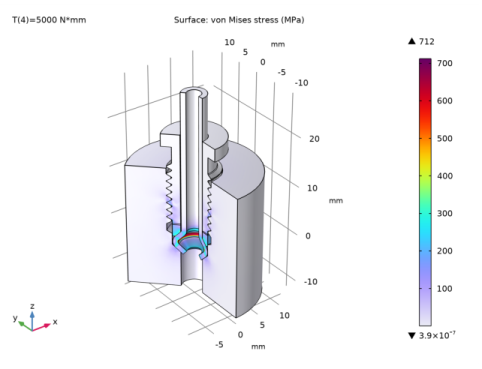

In the Model Builder window, under Component 2 (comp2) right-click Solid Mechanics (solid) and choose Pairs>Contact.

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Pairs list, choose Contact Pair 1 (p1), Contact Pair 2 (p2), and Contact Pair 3 (p3).

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file pipe_fitting_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Equation-Based Contributions.

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

From the list, choose Diagonal.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1>Segregated 1 node, then click Solid Mechanics.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|