|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object blk1, select Boundary 3 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

On the object r1, select Points 1–4 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

In the Model Builder window, expand the Linear Elastic Material 2 node, then click Shell Local System 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

In the Settings window for Prescribed Displacement/Rotation, locate the Prescribed Displacement section.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

Specify the M vector as

|

|

4

|

|

1

|

|

2

|

|

3

|

Specify the M vector as

|

|

4

|

|

1

|

|

2

|

|

3

|

Specify the M vector as

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Global Definitions>Load and Constraint Groups click Load Group 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Add three times.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

In the Settings window for Point Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Shell>Strain>Strain tensor (local)>shell.el11 - Strain tensor (local), 11 component.

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Find the Parameters subsection. In the table, enter the following settings:

|

|

6

|

Click

|

|

1

|

|

2

|

In the Settings window for Point Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Shell>Strain>Strain tensor (local)>shell.el22 - Strain tensor (local), 22 component.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|

Click

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Point Evaluation 1 and choose Duplicate.

|

|

3

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file frame_with_cutout_SN_curve.txt.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file frame_with_cutout_load.txt.

|

|

6

|

|

7

|

Click

|

|

8

|

Find the Functions subsection. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study: Generalized Loads.

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Cycle Counting Parameters section. Find the Discretization subsection. In the Nr text field, type 20.

|

|

8

|

|

9

|

|

10

|

|

11

|

Click

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Shell (shell).

|

|

4

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Fatigue.

|

|

5

|

|

6

|

|

1

|

|

2

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Fatigue Usage Factor (ftg), Stress Cycle Distribution (ftg), and Fatigue Usage Distribution (ftg).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

|

3

|

|

4

|

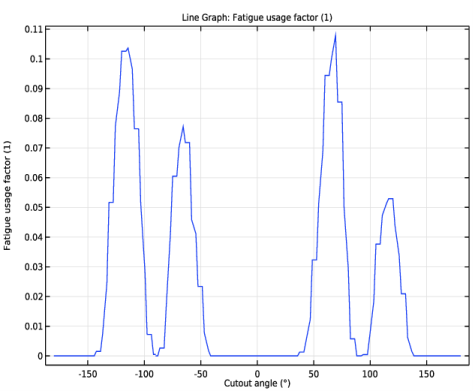

In the Expression text field, type

|

|

5

|

|

6

|

Select the Description check box.

|

|

7

|

In the associated text field, type Cutout angle.

|

|

8

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Fatigue Usage Factor Outside (ftg) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Stress Cycle Distribution Outside (ftg) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Stress Cycle Distribution Outside (ftg) node, then click Matrix Histogram 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Fatigue Usage Distribution Outside (ftg) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Fatigue Usage Distribution Outside (ftg) node, then click Matrix Histogram 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Study: Generalized Loads and Study: Fatigue Outside.

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Cycle Counting Parameters section. Find the Discretization subsection. In the Nr text field, type 20.

|

|

8

|

|

9

|

|

10

|

|

11

|

Click Add three times.

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Shell (shell) and Fatigue Outside (ftg).

|

|

4

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Fatigue.

|

|

5

|

|

6

|

|

1

|

|

2

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Fatigue Usage Factor (ftg2), Stress Cycle Distribution (ftg2), and Fatigue Usage Distribution (ftg2).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Fatigue Usage Factor Inside (ftg2) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Fatigue Usage Factor Inside (ftg2) node, then click Line Graph 1.

|

|

2

|

|

3

|

|

4

|

In the Expression text field, type

|

|

5

|

|

6

|

Select the Description check box.

|

|

7

|

In the associated text field, type Cutout angle.

|

|

8

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Stress Cycle Distribution Inside (ftg2) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Stress Cycle Distribution Inside (ftg2) node, then click Matrix Histogram 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Fatigue Usage Distribution Inside (ftg2) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Fatigue Usage Distribution Inside (ftg2) node, then click Matrix Histogram 1.

|

|

2

|

|

3

|

|

4

|

|

5

|