|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Electrodeposition, Deformed Geometry>Electrodeposition, Tertiary with Supporting Electrolyte.

|

|

3

|

Click Add.

|

|

4

|

|

5

|

In the Concentrations table, enter the following settings:

|

|

6

|

Click

|

|

7

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Time Dependent with Initialization.

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

1

|

|

2

|

On the object uni1, select Point 5 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file cu_deposition_suppressor_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file cu_deposition_suppressor_variables.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck (tcd) click Electrolyte 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Electrolyte Current Conduction section. From the σl list, choose User defined. In the associated text field, type sigmal.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

In the Settings window for Electrode Surface, click to expand the Dissolving-Depositing Species section.

|

|

8

|

Click

|

|

10

|

|

11

|

Click

|

|

12

|

Click

|

|

14

|

Locate the Electrode Phase Potential Condition section. In the φs,ext text field, type phis_cathode.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Stoichiometric coefficients for dissolving-depositing species: table, enter the following settings:

|

|

6

|

|

7

|

|

8

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the Reaction rate for adsorbing-desorbing species table, enter the following settings:

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Nondeforming Boundary 1 (ndbdg1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

4

|

In the table, clear the Solve for check boxes for Nondeforming Boundary 1 (ndbdg1) and Deforming Electrode Surface 1 (desdg1).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Concentration, Cl, 3D (tcd) node, then click Contour 1.

|

|

2

|

In the Settings window for Contour, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>Species cCl>cCl - Concentration - mol/m³.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

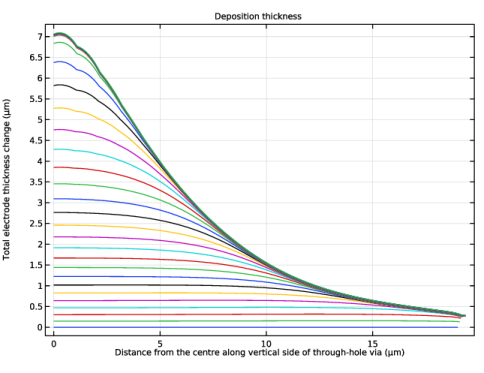

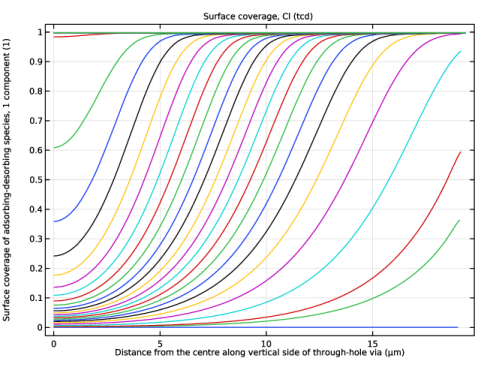

Select the Description check box.

|

|

10

|

In the associated text field, type Distance from the centre along vertical side of through-hole via.

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|