|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Tertiary Current Distribution, Nernst-Planck>Tertiary, Supporting Electrolyte (tcd).

|

|

3

|

Click Add.

|

|

4

|

|

5

|

In the Concentrations table, enter the following settings:

|

|

6

|

|

7

|

Click Add.

|

|

8

|

Click

|

|

9

|

|

10

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file oxide_jacking_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

On the object fin, select Domains 1, 3, and 4 only.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file oxide_jacking_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file oxide_jacking_sigma.txt.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file oxide_jacking_D_O2.txt.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Built-in>Concrete.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck (tcd) click Electrolyte 1.

|

|

2

|

|

3

|

|

4

|

Locate the Electrolyte Current Conduction section. From the σl list, choose User defined. In the associated text field, type sigma(PS).

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

In the Settings window for Electrode Surface, click to expand the Dissolving-Depositing Species section.

|

|

4

|

Click

|

|

6

|

Click

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck (tcd)>Electrode Surface 1 click Electrode Reaction 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Equilibrium Potential section. From the Eeq list, choose User defined. In the associated text field, type Eeq_O2.

|

|

6

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Cathodic Tafel equation.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Stoichiometric coefficients for dissolving-depositing species: table, enter the following settings:

|

|

6

|

Locate the Equilibrium Potential section. From the Eeq list, choose User defined. In the associated text field, type Eeq_Fe.

|

|

7

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Anodic Tafel equation.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

Locate the Equilibrium Potential section. From the Eeq list, choose User defined. In the associated text field, type Eeq_H2.

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Cathodic Tafel equation.

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck (tcd) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

Find the Damage evolution subsection. From the σts list, choose User defined. In the associated text field, type sigmap.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 1 node, then click Fully Coupled 1.

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

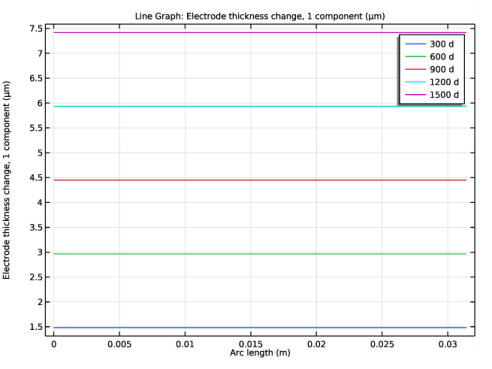

In the Settings window for 1D Plot Group, type Corrosion Product Layer Thickness in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>Dissolving-depositing species>Electrode thickness change - m>tcd.sb_oxide - Electrode thickness change, 1 component.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

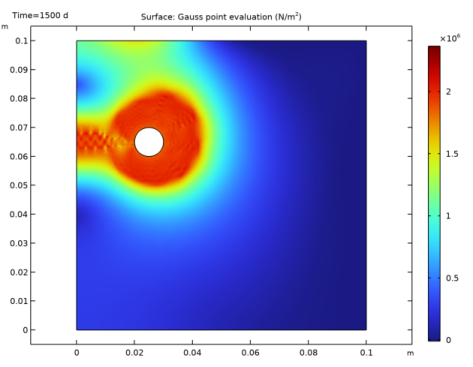

In the Settings window for 2D Plot Group, type First Principal Stress Analysis in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

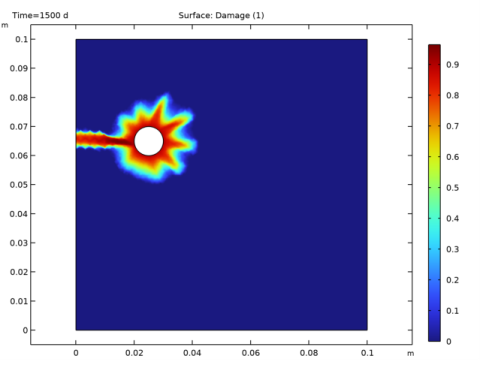

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Damage>solid.dmg - Damage.

|

|

1

|

|

2

|

|

1

|

|

2

|

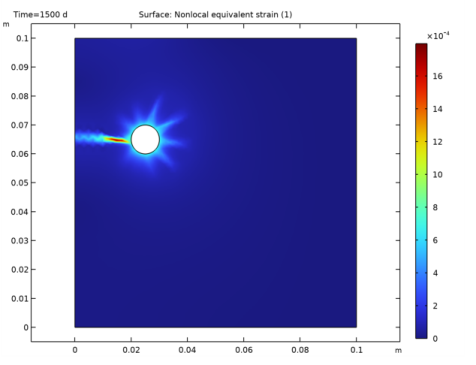

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Damage>solid.eeqnl - Nonlocal equivalent strain.

|

|

3

|