|

|

Af

|

|

|

Ea

|

30·103 J/mol

|

|

R_const (built in constant)

|

|

1

|

|

2

|

In the Select Physics tree, select Chemical Species Transport>Reacting Flow in Porous Media>Transport of Diluted Species.

|

|

3

|

Click Add.

|

|

4

|

|

5

|

|

6

|

In the Concentrations table, enter the following settings:

|

|

7

|

Click

|

|

8

|

|

9

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file porous_reactor_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Difference, type Walls and free-porous media interfaces in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

In the Add dialog box, in the Selections to subtract list, choose Symmetry plane, Inlet species B, Inlet species A, and Outlet.

|

|

10

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file porous_reactor_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

1

|

In the Model Builder window, expand the Porous Material 1 (pmat1) node, then click Fluid (pmat1.fluid).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species in Porous Media (tds)>Porous Medium 1 click Fluid 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1 right-click Size 1 and choose Duplicate.

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

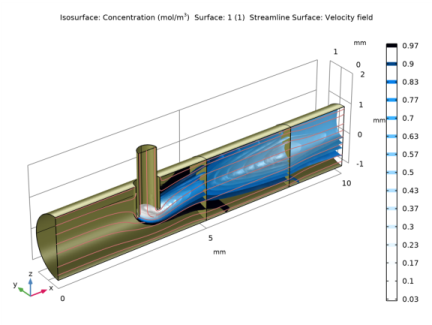

In the Settings window for 3D Plot Group, type Concentration, c_A, Isosurface in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Isosurface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species in Porous Media>Species c_A>c_A - Concentration - mol/m³.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click Define custom colors.

|

|

9

|

Click Add to custom colors.

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

Click Define custom colors.

|

|

13

|

Click Add to custom colors.

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Concentration, c_B, Isosurface in the Label text field.

|

|

1

|

In the Model Builder window, expand the Concentration, c_B, Isosurface node, then click Isosurface 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Concentration, c_C, Isosurface in the Label text field.

|

|

1

|

In the Model Builder window, expand the Concentration, c_C, Isosurface node, then click Isosurface 1.

|

|

2

|

|

3

|

|

4

|