|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file microreactor_optimization_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Variables>phi - Local reaction rate - mol/(m³·s).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Laminar Flow (spf) and choose Volume Force.

|

|

3

|

|

4

|

Specify the F vector as

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

5

|

|

1

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1, Ctrl-click to select Size 1 and Corner Refinement 1.

|

|

2

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 1 (comp1)>Definitions>comp1.obj - Objective Function - mol/(m³·s).

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Advanced section. From the Compensate for nojac terms list, choose Off to avoid warnings in the log.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

1

|

In the Model Builder window, expand the Results>Topology Optimization node, then click Output material volume factor.

|

|

2

|

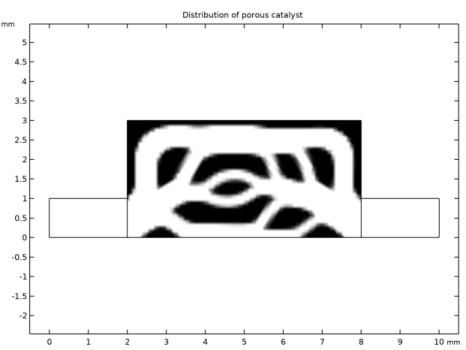

In the Settings window for 2D Plot Group, type Distribution of porous catalyst in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Solver>Objective functions>opt.obj1 - Objective Function - mol/(m³·s).

|

|

3

|

Click

|

|

1

|

Go to the Table window.

|