|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Reaction Engineering (re) and choose Reaction.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file carbon_deposition_parameters.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file carbon_deposition_variables.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Reaction Engineering (re) click 1: CH4=>C+2H2.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the Volumetric species table, enter the following settings:

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_a - Concentration - mol/m³.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Concentration Comparison (re) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

5

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics Interfaces section. Find the Chemical species transport subsection. From the list, choose Transport of Concentrated Species: New.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file carbon_deposition_2D_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

On the object r2, select Points 2 and 3 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

On the object uni1, select Points 6 and 7 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

In the Dependent variables table, enter the following settings:

|

|

1

|

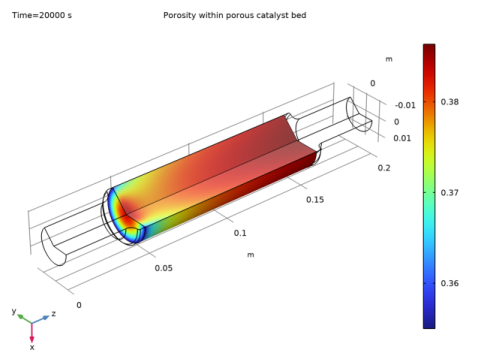

In the Model Builder window, under Component 2 (comp2)>Porosity Change (dode) click Distributed ODE 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Chemistry 1 (chem) node, then click Species: CH4.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Species Transport Expressions section. From the Thermal conductivity list, choose User defined.

|

|

5

|

|

1

|

In the Model Builder window, under Component 2 (comp2) click Transport of Concentrated Species (tcs).

|

|

2

|

In the Settings window for Transport of Concentrated Species, locate the Transport Mechanisms section.

|

|

3

|

|

1

|

In the Model Builder window, expand the Transport of Concentrated Species (tcs) node, then click Transport Properties 1.

|

|

2

|

|

1

|

|

3

|

|

4

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Diffusion section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Heat Transfer in Porous Media 1 (ht)>Porous Medium 1 node, then click Fluid 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Heat Conduction, Porous Matrix section. From the ks list, choose User defined. In the associated text field, type kt_cat.

|

|

6

|

Locate the Thermodynamics, Porous Matrix section. From the ρs list, choose User defined. In the associated text field, type rho_cat.

|

|

7

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Heat Transfer in Porous Media 1 (ht) click Heat Source 1.

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Chemistry 1 (chem), Transport of Concentrated Species (tcs), Heat Transfer in Porous Media 1 (ht), and Porosity Change (dode).

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check box for Reaction Engineering (re).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 2 (comp2)>Heat Transfer in Porous Media 1>Temperature>T - Temperature - K.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Title section. Locate the Plot Settings section. Clear the Plot dataset edges check box.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

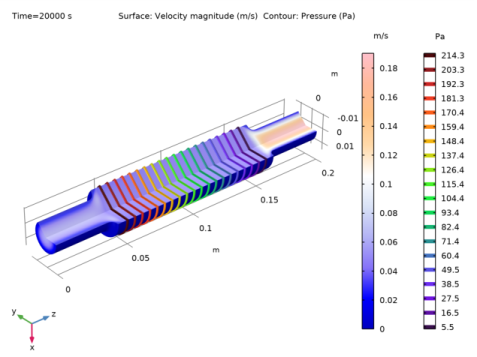

In the Settings window for Contour, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 2 (comp2)>Laminar Flow 1>Velocity and pressure>p - Pressure - Pa.

|

|

3

|

Click to expand the Title section. Locate the Coloring and Style section. From the Contour type list, choose Tube.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

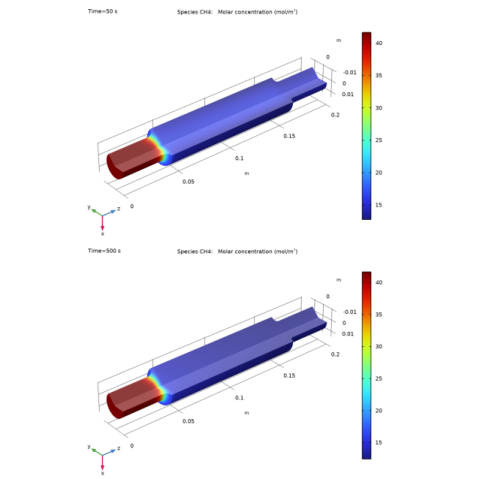

In the Settings window for 1D Plot Group, type Concentration CH4, Porous Catalyst Bed Center in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

In the associated text field, type Length porous catalytic bed (m).

|

|

10

|

|

11

|

In the associated text field, type Concentration (mol/m<sup>3</sup>).

|

|

12

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 2 (comp2)>Transport of Concentrated Species>Species wCH4>tcs.c_wCH4 - Molar concentration - mol/m³.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 2 (comp2)>Transport of Concentrated Species>Species wH2>tcs.c_wH2 - Molar concentration - mol/m³.

|

|

3

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Chemistry 1 (chem), Transport of Concentrated Species (tcs), Heat Transfer in Porous Media 1 (ht), Laminar Flow 1 (spf), and Porosity Change (dode).

|