|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the y text field, type c*0.594689181*(0.298222773*sqrt(s)-0.127125232*s-0.357907906*s^2+0.291984971*s^3-0.105174696*s^4).

|

|

5

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object uni1, select Domain 2 only.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Dependent variable quantity table, enter the following settings:

|

|

5

|

|

6

|

In the Source term quantity table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Turbulent Flow, SST (spf) click Fluid Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Specify the u vector as

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

Click to expand the Control Entities section. Clear the Smooth across removed control entities check box.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Streamline Positioning section. From the Positioning list, choose Starting-point controlled.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Turbulent Flow, SST>Stationary with Initialization.

|

|

4

|

|

5

|

|

1

|

In the Settings window for Wall Distance Initialization, locate the Physics and Variables Selection section.

|

|

2

|

|

3

|

Click to expand the Values of Dependent Variables section. Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Values of Dependent Variables section. Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

5

|

|

6

|

|

7

|

Click

|

|

9

|

|

1

|

|

3

|

|

5

|

|

6

|

Click

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

Click Import.

|

|

4

|

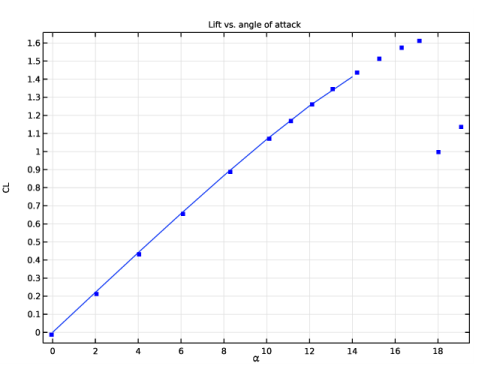

Browse to the model’s Application Libraries folder and double-click the file naca0012_airfoil_Ladson_CL.dat.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

|

1

|

|

2

|

|

3

|

Click Import.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file naca0012_airfoil_Gregory_OReilly_Cp.dat.

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type (x-xLE)/c.

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Streamline Positioning section. From the Positioning list, choose Starting-point controlled.

|

|

6

|

|

7

|

|

8

|

|

9

|