|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Single-Phase Flow>Rotating Machinery, Fluid Flow>Laminar Flow.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file baffled_mixer.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

Click to expand the Wall Movement section. From the Translational velocity list, choose Zero (Fixed wall).

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

Locate the Element Size Parameters section. In the Maximum element growth rate text field, type 1.2.

|

|

5

|

|

1

|

In the Model Builder window, expand the Boundary Layers 1 node, then click Boundary Layer Properties 1.

|

|

2

|

In the Settings window for Boundary Layer Properties, in the Graphics window toolbar, click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Boundary Layer Properties, in the Graphics window toolbar, click

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

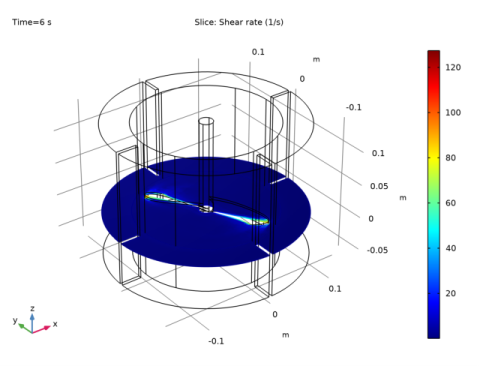

In the Settings window for Slice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>spf.sr - Shear rate - 1/s.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

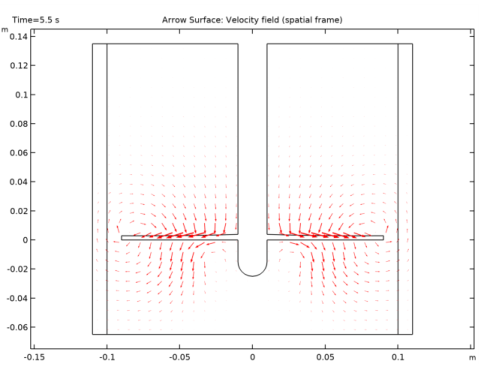

Locate the Arrow Positioning section. Find the x grid points subsection. In the Points text field, type 30.

|

|

7

|

|

8

|

|

10

|