|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Time Dependent with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file li_battery_tutorial_2d_geom_sequence.mph.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the tree, select Battery>Electrolytes>LiPF6 in 1:2 EC:DMC and p(VdF-HFP) (Polymer, Li-ion Battery).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Lithium-Ion Battery (liion) and choose Porous Electrode.

|

|

3

|

|

4

|

From the Electrolyte material list, choose LiPF6 in 1:2 EC:DMC and p(VdF-HFP) (Polymer, Li-ion Battery) (mat1).

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

From the Eeq list, choose User defined. Click to expand the Heat of Reaction section. From the dEeq/dT list, choose User defined.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click Replace.

|

|

7

|

|

8

|

Click

|

|

9

|

|

10

|

|

11

|

|

12

|

Click Add.

|

|

13

|

|

1

|

|

2

|

|

1

|

|

2

|

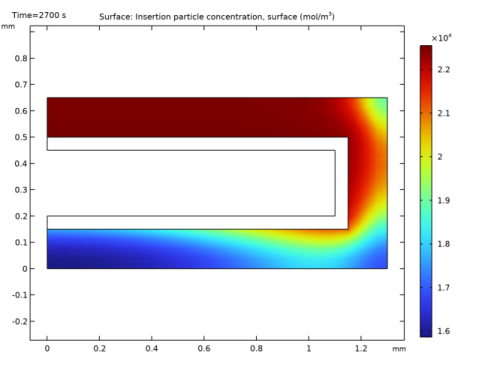

In the Settings window for 2D Plot Group, type Lithium Concentration on Particle Surface in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Lithium-Ion Battery>Particle intercalation>liion.cs_surface - Insertion particle concentration, surface - mol/m³.

|

|

3

|

|

1

|

|

2

|

|

3

|

From the Component list, choose Extra Dimension from Particle Intercalation 1 (liion_pce1_pin1_xdim).

|

|

1

|

|

2

|

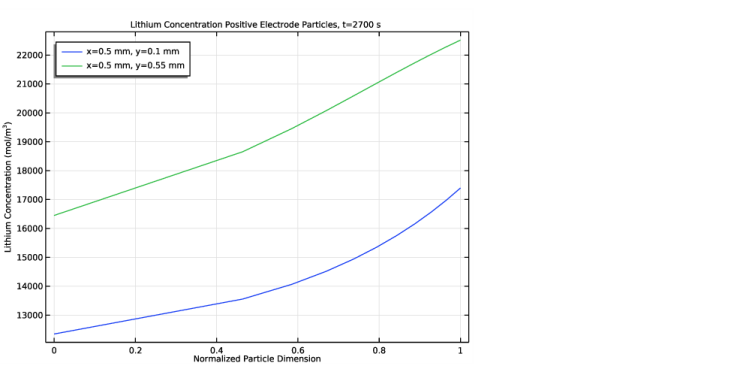

In the Settings window for 1D Plot Group, type Lithium Concentration in Positive Electrode Particles in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the y-Axis Data section. In the Expression text field, type comp1.atxd2(5e-4,1e-4,liion.cs_pce1).

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Normalized Particle Dimension.

|

|

7

|

|

8

|

In the associated text field, type Lithium Concentration (mol/m<sup>3</sup>).

|

|

9

|

|

10

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Select the object r3 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|