|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Electromagnetics-Structure Interaction>Piezoelectricity>Piezoelectricity, Solid.

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Acoustics>Pressure Acoustics>Pressure Acoustics, Frequency Domain (acpr).

|

|

5

|

Click Add.

|

|

6

|

In the Select Physics tree, select Acoustics>Thermoviscous Acoustics>Thermoviscous Acoustics, Frequency Domain (ta).

|

|

7

|

Click Add.

|

|

8

|

Click

|

|

9

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Electrostatics>Small-Signal Analysis, Frequency Domain.

|

|

10

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file piezo_mems_speaker_parameters.txt.

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file piezo_mems_speaker_geom_sequence.mph.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

7

|

|

9

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Scaling section. From the Physics list, choose Pressure Acoustics, Frequency Domain (acpr).

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

6

|

|

7

|

In the tree, select Built-in>Silicon.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Piezoelectric Material 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Electrostatics (es) click Charge Conservation, Piezoelectric 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Pressure Acoustics, Frequency Domain (acpr).

|

|

2

|

In the Settings window for Pressure Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

3

|

|

4

|

Click to expand the Discretization section.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Exterior Field Calculation section. From the Condition in the x = x0 plane list, choose Symmetric/Infinite sound hard boundary.

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Thermoviscous Boundary Layer Impedance, locate the Fluid Properties section.

|

|

3

|

|

1

|

|

3

|

In the Settings window for Thermoviscous Boundary Layer Impedance, locate the Fluid Properties section.

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Thermoviscous Acoustics, Frequency Domain (ta).

|

|

2

|

In the Settings window for Thermoviscous Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Thermoviscous Acoustic-Structure Boundary, locate the Boundary Selection section.

|

|

3

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Acoustic-Thermoviscous Acoustic Boundary, locate the Boundary Selection section.

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

In the associated text field, type dvisc*4.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

Locate the Element Size Parameters section. In the Maximum element size text field, type lambda_min/6.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

In the associated text field, type dvisc*15.

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Pressure Acoustics, Frequency Domain (acpr) and Thermoviscous Acoustics, Frequency Domain (ta).

|

|

4

|

In the table, clear the Solve for check boxes for Thermoviscous Acoustic-Structure Boundary 1 (tsb1) and Acoustic-Thermoviscous Acoustic Boundary 1 (atb1).

|

|

1

|

|

2

|

|

3

|

In the Frequencies text field, type 10 5000 6000 7000 8000 9000 9200 9400 9475 9550 9600 9650 9725 9800 10000 10200 11000 12000 20000.

|

|

4

|

Find the Values of linearization point subsection. Select the Include geometric nonlinearity check box.

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2 node.

|

|

4

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2>Suggested Iterative Solver (GMRES with Direct Precon.) (pze1_tsb1_atb1) and choose Enable.

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Acoustic pressure.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Acoustic Pressure, Isosurfaces (ta+acpr) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Acoustic Pressure, Isosurfaces (ta+acpr) node, then click Isosurface 1.

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Acoustic pressure.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Logarithmic Thermoviscous Losses (ta) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Logarithmic Thermoviscous Losses (ta) node, then click Slice 1.

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type log10(Thermoviscous losses).

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

kΩ

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

Clear the Color check box.

|

|

15

|

|

16

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Results>Model Thumbnail right-click Slice 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Clear the Color check box.

|

|

9

|

|

1

|

|

1

|

|

2

|

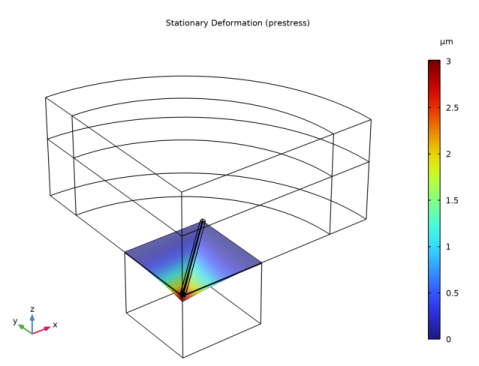

In the Settings window for 3D Plot Group, type Stationary Deformation (prestress) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1) node, then click Results>Stationary Deformation (prestress)>Surface 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object uni1, select Domains 1, 6, 13, and 17 only.

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Work Plane 1 (wp1) and choose Extrude.

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

Select the object cyl1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object par1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object mov1, select Domains 2, 4, and 6 only.

|

|

5

|

On the object par1, select Domains 1, 3, and 5 only.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Layers section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

Select the object cyl2 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object par2, select Domains 1–4, 9, 10, 13, 14, 17, and 18 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Select the object del2 only.

|

|

3

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

4

|

|

1

|

|

2

|

Select the object uni1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object par3 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object par4, select Domains 1–14, 17, 21, 48, and 55 only.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Output Entities section. From the Include entity if list, choose All vertices inside cylinder.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Thermoviscous Domain 1 and Thermoviscous Domain 2.

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

Click

|

|

8

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

Click

|

|

8

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

Click

|

|

8

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

1

|

|

2

|

In the Settings window for Difference Selection, type Pressure Acoustics Domains in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

Click

|

|

8

|

In the Add dialog box, in the Selections to subtract list, choose Thermoviscous Domains and Structural Domains.

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Thermoviscous Domains and Structural Domains.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Thermoviscous Domains and Pressure Acoustics Domains.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

Click

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Explicit Selection, type Exterior Field Boundaries in the Label text field.

|

|

3

|

|

4

|

On the object del3, select Boundaries 23 and 49 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object del3, select Boundaries 33, 42, 62, 71, 89, 96, 107, and 129 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object del3, select Boundaries 28, 39, 59, 67, 86, 93, 102, and 126 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|