|

|

1

|

|

2

|

In the Select Physics tree, select Acoustics>Pressure Acoustics>Pressure Acoustics, Frequency Domain (acpr).

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Acoustics>Thermoviscous Acoustics>Thermoviscous Acoustics, Frequency Domain (ta).

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file generic_711_coupler_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file generic_711_coupler_transfer_impedance.txt.

|

|

6

|

|

7

|

Click

|

|

8

|

Find the Functions subsection. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file generic_711_coupler_mic_response.txt.

|

|

6

|

|

7

|

Click

|

|

8

|

Find the Functions subsection. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file generic_711_coupler.mphbin.

|

|

5

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file generic_711_coupler_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Pressure Acoustics, Frequency Domain (acpr).

|

|

2

|

In the Settings window for Pressure Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Pressure Acoustics, Frequency Domain (acpr) click Pressure Acoustics 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Thermoviscous Acoustics, Frequency Domain (ta) click Thermoviscous Acoustics Model 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Settings window for Thermoviscous Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Acoustic-Thermoviscous Acoustic Boundary, locate the Boundary Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Settings window for Pressure Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Pressure Acoustics, Frequency Domain 2 (acpr2) click Pressure Acoustics 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Settings window for Pressure Acoustics, Frequency Domain, click to expand the Dependent Variables section.

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Thermoviscous Acoustics, Frequency Domain (ta).

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Study 2 - Narrow Region Acoustics click Step 1: Frequency Domain.

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 2 - Narrow Region Acoustics>Solver Configurations>Solution 2 (sol2)>Stationary Solver 1 node.

|

|

4

|

Right-click Study 2 - Narrow Region Acoustics>Solver Configurations>Solution 2 (sol2)>Stationary Solver 1 and choose Fully Coupled.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Thermoviscous Acoustics, Frequency Domain (ta).

|

|

5

|

Find the Multiphysics couplings in study subsection. In the table, clear the Solve check box for Acoustic-Thermoviscous Acoustic Boundary 1 (atb1).

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

10

|

|

11

|

In the tree, select Component 1 (Comp1)>Pressure Acoustics, Frequency Domain 2 (Acpr2)>Narrow Region Acoustics 1 and Component 1 (Comp1)>Pressure Acoustics, Frequency Domain 2 (Acpr2)>Narrow Region Acoustics 2.

|

|

12

|

Click

|

|

13

|

Right-click Study 3 - Pressure Acoustics>Step 1: Frequency Domain and choose Get Initial Value for Step.

|

|

1

|

In the Model Builder window, expand the Study 3 - Pressure Acoustics>Solver Configurations>Solution 3 (sol3)>Stationary Solver 1 node.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

8

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

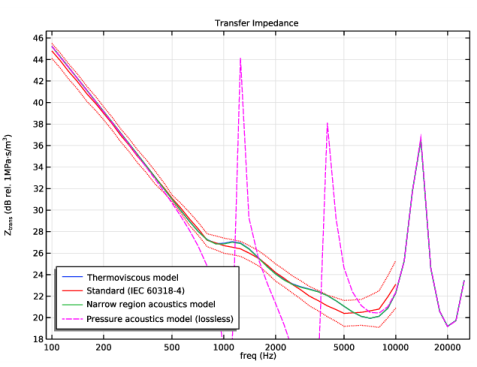

In the associated text field, type Z<sub>trans</sub> (dB rel. 1MPa·s/m<sup>3</sup>).

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

Locate the Data section. From the Dataset list, choose Study 1 - Thermoviscous Model/Solution 1 (sol1).

|

|

6

|

|

7

|

In the Parameter values list, choose values from 100 to 10000.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

5

|

|

1

|

In the Model Builder window, under Results>Transfer Impedance right-click Global 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

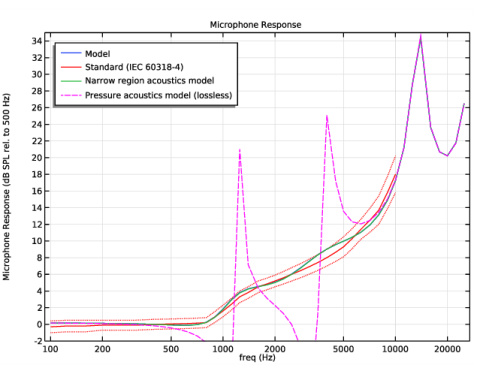

Locate the Plot Settings section. In the y-axis label text field, type Microphone Response (dB SPL rel. to 500 Hz).

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Z<sub>in</sub> (dB rel. 1MPa·s/m<sup>3</sup>).

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|