|

|

•

|

A cylindrical domain — adjoined at the inlet plane and extending to the terminal plane, z = 2.86393 — extends the modeling domain into a region where you can consider the mean flow as being uniform. This allows you to impose the simple boundary condition of a constant velocity potential and a vanishing tangential velocity for the background flow at the terminal plane.

|

|

•

|

Sound hard — the normal component of the acoustic particle velocity vanishes at the boundary.

|

|

•

|

Impedance — the normal component of the acoustic particle velocity is related to the particle displacement through the equation

|

|

•

|

Compressible Potential Flow (cpf) — for modeling the background mean-flow velocity field as a potential flow (a lossless and irrotational flow).

|

|

•

|

Linearized Potential Flow, Boundary Mode (aebm) — for calculating the boundary eigenmode to be used as the source of the acoustic noise in the background mean-flow.

|

|

•

|

Linearized Potential Flow, Frequency Domain (ae, ae2) — for modeling the time-harmonic acoustic field above and below the source plane.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Acoustics>Aeroacoustics>Linearized Potential Flow, Boundary Mode (aebm).

|

|

5

|

Click Add.

|

|

6

|

|

7

|

In the Select Physics tree, select Acoustics>Aeroacoustics>Linearized Potential Flow, Frequency Domain (ae).

|

|

8

|

Click Add twice.

|

|

9

|

Click

|

|

10

|

|

11

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file flow_duct_parameters.txt.

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object imp1, select Boundary 34 only.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Compressible Potential Flow (cpf) click Compressible Potential Flow Model 1.

|

|

2

|

In the Settings window for Compressible Potential Flow Model, locate the Compressible Potential Flow Model section.

|

|

3

|

|

1

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Linearized Potential Flow, Boundary Mode (aebm).

|

|

2

|

In the Settings window for Linearized Potential Flow, Boundary Mode, locate the Boundary Selection section.

|

|

3

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Linearized Potential Flow, Boundary Mode (aebm) click Linearized Potential Flow Model 1.

|

|

2

|

In the Settings window for Linearized Potential Flow Model, locate the Linearized Potential Flow Model section.

|

|

3

|

|

4

|

|

5

|

Specify the V vector as

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Background and Source/Parametric Solutions 1 (sol3).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Data section. From the Dataset list, choose Study 1 - Background and Source/Parametric Solutions 1 (sol3).

|

|

6

|

Click

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

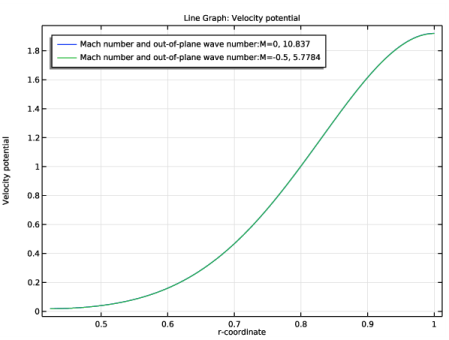

In the Settings window for 1D Plot Group, type Boundary Mode Potential: phi_b in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Background and Source/Parametric Solutions 1 (sol3).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

Find the Prefix and suffix subsection. In the Prefix text field, type Mach number and out-of-plane wave number: .

|

|

8

|

|

9

|

|

10

|

|

1

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Linearized Potential Flow, Frequency Domain (ae).

|

|

3

|

In the Settings window for Linearized Potential Flow, Frequency Domain, click to expand the Equation section.

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Linearized Potential Flow, Frequency Domain 2 (ae2).

|

|

3

|

In the Settings window for Linearized Potential Flow, Frequency Domain, locate the Linearized Potential Flow Equation Settings section.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Linearized Potential Flow, Frequency Domain 2 (ae2) click Linearized Potential Flow Model 1.

|

|

2

|

In the Settings window for Linearized Potential Flow Model, locate the Linearized Potential Flow Model section.

|

|

3

|

|

4

|

|

5

|

Specify the V vector as

|

|

1

|

Right-click Component 1 (comp1)>Linearized Potential Flow, Frequency Domain 2 (ae2)>Linearized Potential Flow Model 1 and choose Duplicate.

|

|

3

|

In the Settings window for Linearized Potential Flow Model, locate the Linearized Potential Flow Model section.

|

|

4

|

Specify the V vector as

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Compressible Potential Flow (cpf) and Linearized Potential Flow, Boundary Mode (aebm).

|

|

4

|

|

5

|

|

6

|

|

7

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Compressible Potential Flow (cpf) and Linearized Potential Flow, Boundary Mode (aebm).

|

|

8

|

|

9

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Some Physics Interfaces>Frequency Domain.

|

|

10

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Compressible Potential Flow (cpf) and Linearized Potential Flow, Boundary Mode (aebm).

|

|

11

|

|

12

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Some Physics Interfaces>Frequency Domain.

|

|

13

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Compressible Potential Flow (cpf) and Linearized Potential Flow, Boundary Mode (aebm).

|

|

14

|

|

15

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Study 2 - Frequency Domain (M = 0, lined) click Step 1: Frequency Domain.

|

|

2

|

|

3

|

|

4

|

Click to expand the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Study 3 - Frequency Domain (M = -0.5, lined) click Step 1: Frequency Domain.

|

|

2

|

|

3

|

|

4

|

Locate the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Study 4 - Frequency Domain (M = 0, hard wall) click Step 1: Frequency Domain.

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

In the tree, select Component 1 (Comp1)>Linearized Potential Flow, Frequency Domain (Ae)>Impedance 1.

|

|

6

|

Click

|

|

7

|

In the tree, select Component 1 (Comp1)>Linearized Potential Flow, Frequency Domain (Ae)>Impedance 2.

|

|

8

|

Click

|

|

9

|

Locate the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Study 5 - Frequency Domain (M = -0.5, hard wall) click Step 1: Frequency Domain.

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

In the tree, select Component 1 (Comp1)>Linearized Potential Flow, Frequency Domain (Ae)>Impedance 1.

|

|

6

|

Click

|

|

7

|

In the tree, select Component 1 (Comp1)>Linearized Potential Flow, Frequency Domain (Ae)>Impedance 2.

|

|

8

|

Click

|

|

9

|

Locate the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Data section. From the Dataset list, choose Study 2 - Frequency Domain (M = 0, lined)/Solution 6 (sol6).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Levels text field, type 0.0001 0.001 0.01 0.02 0.04 0.06 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Levels text field, type 0.0001 0.001 0.01 0.02 0.04 0.06 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 3 - Frequency Domain (M = -0.5, lined)/Solution 7 (sol7).

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 4 - Frequency Domain (M = 0, hard wall)/Solution 8 (sol8).

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Pressure: M = -0.5, hard wall in the Label text field.

|

|

3

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 5 - Frequency Domain (M = -0.5, hard wall)/Solution 9 (sol9).

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Global Evaluation: W_src (M = 0) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - Background and Source/Parametric Solutions 1 (sol3).

|

|

4

|

|

5

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

Click

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Global Evaluation: W_src (M = -0.5) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Global Evaluation: W_inl (M = 0, lined) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Frequency Domain (M = 0, lined)/Solution 6 (sol6).

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Global Evaluation: W_inl (M = -0.5, lined) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 3 - Frequency Domain (M = -0.5, lined)/Solution 7 (sol7).

|

|

4

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Global Evaluation: Attenuation (M = 0, lined) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 - Frequency Domain (M = 0, lined)/Solution 6 (sol6).

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Global Evaluation: Attenuation (M = -0.5, lined) in the Label text field.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|